It is time we had a new colour range. Certainly not because of fashion’s whirlpool pressures or a feverish Pantone compliance with latest trends, but because times change and it is important to be aware that they have.

Yarn and knit through

the lens of colour

And above all, as our experience in this business has grown, we have become more demanding of our products. It is also colour’s fault. Our perception of colour is permanently unstable, depending on place, temperature, light and the times, so choosing a colour in isolation and out of context always makes it possible that another might be better, because it would be more this or less that. Removed from the colour chart, however exhaustive, the hue that we thought was autonomous starts wandering and attaches itself to everything it juxtaposes or covers. Objects, spaces, places, inside, outside, during the day, at night are all conditions that highlight colour’s relativity. Texaa is open to these principles and works with them. For us at Texaa, colour is relational. It is a prism through which we conduct our business and assert our beliefs.

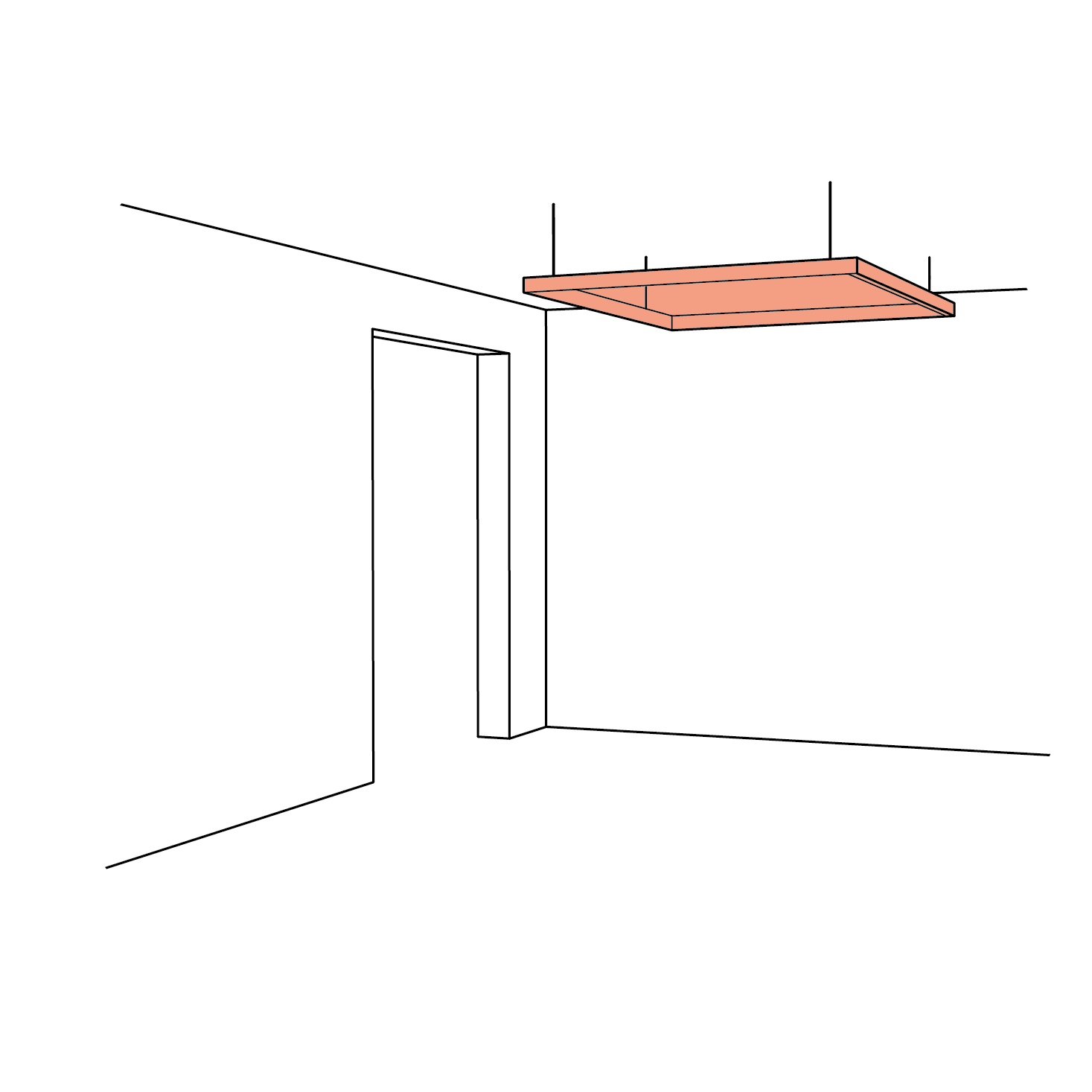

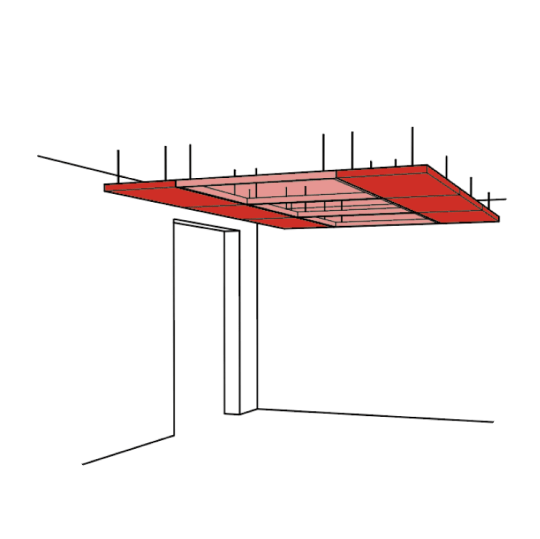

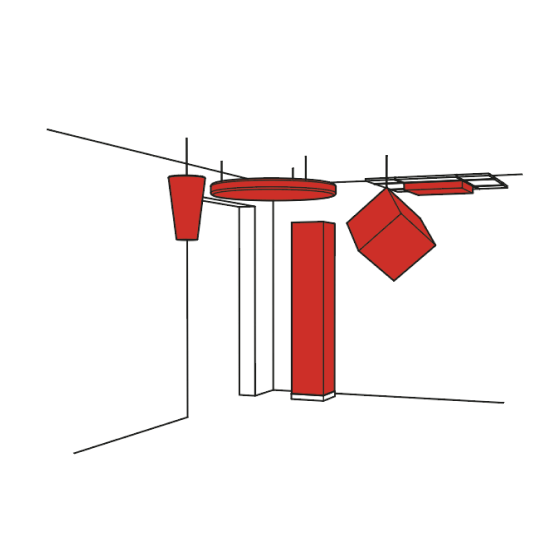

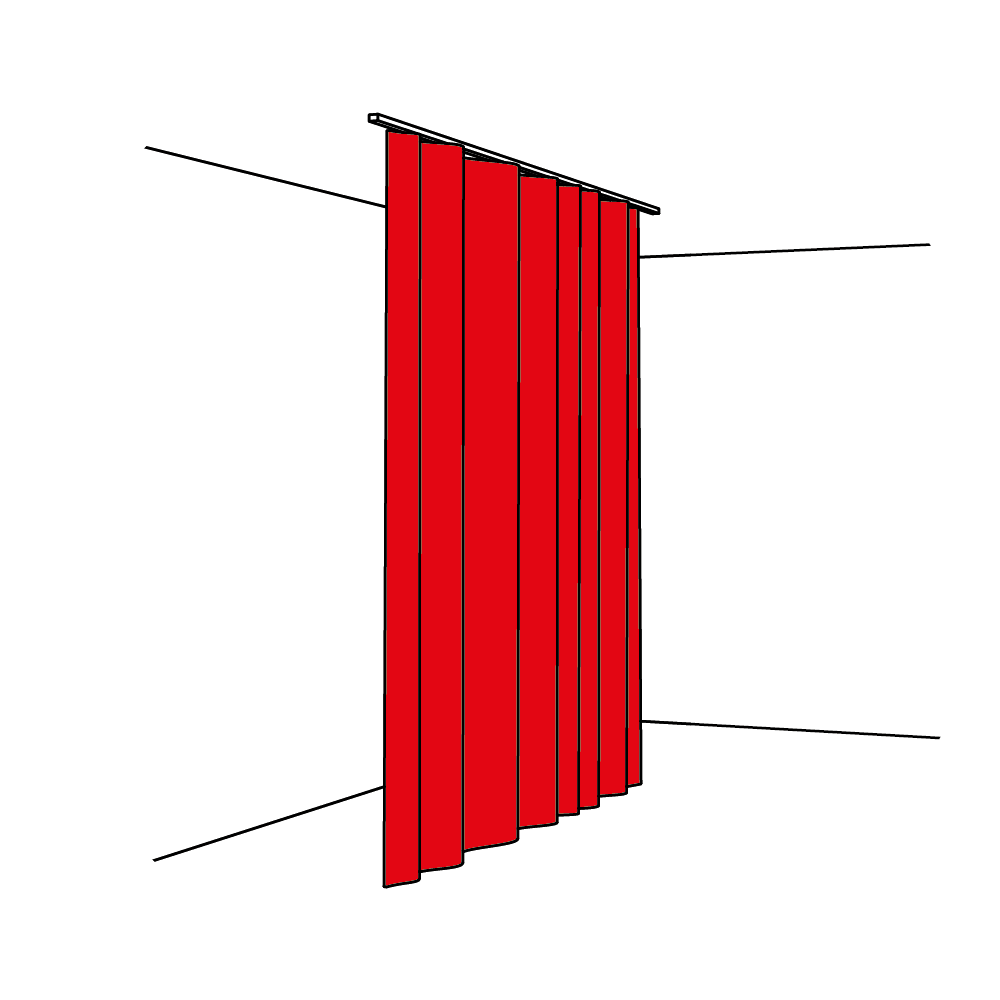

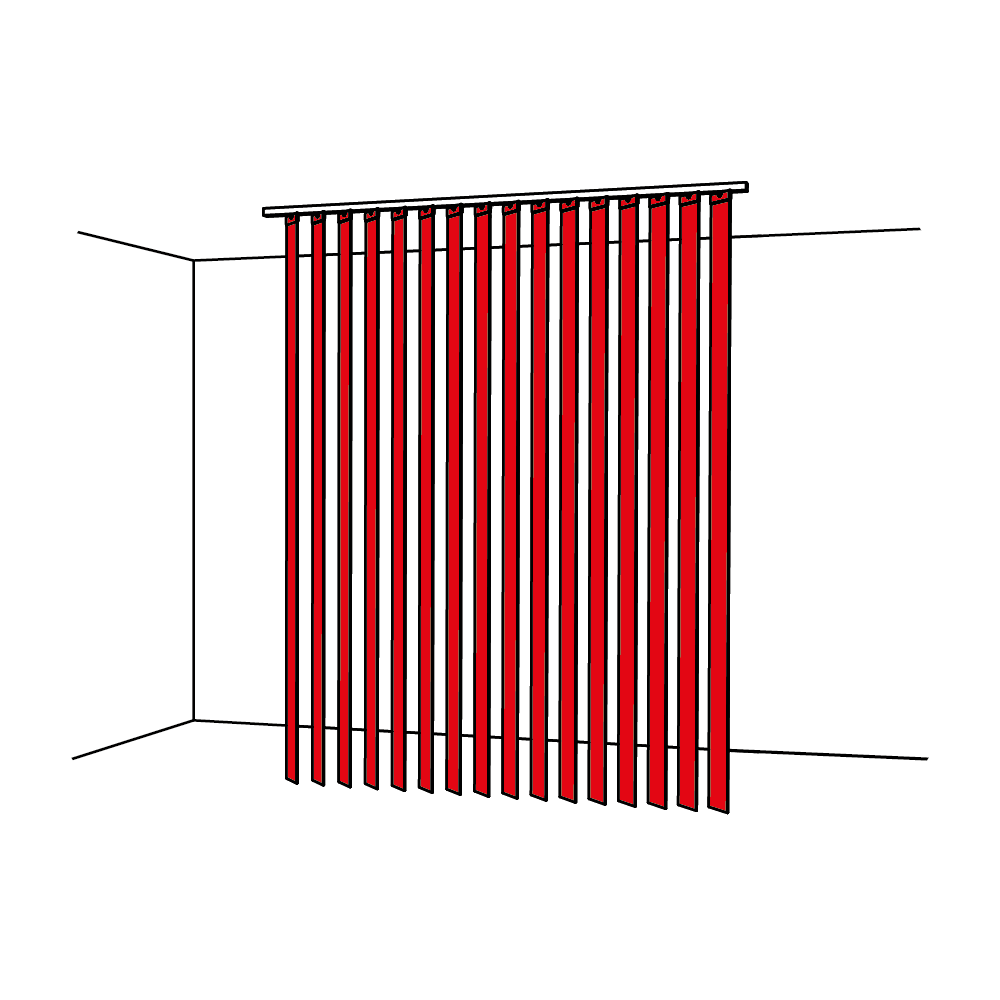

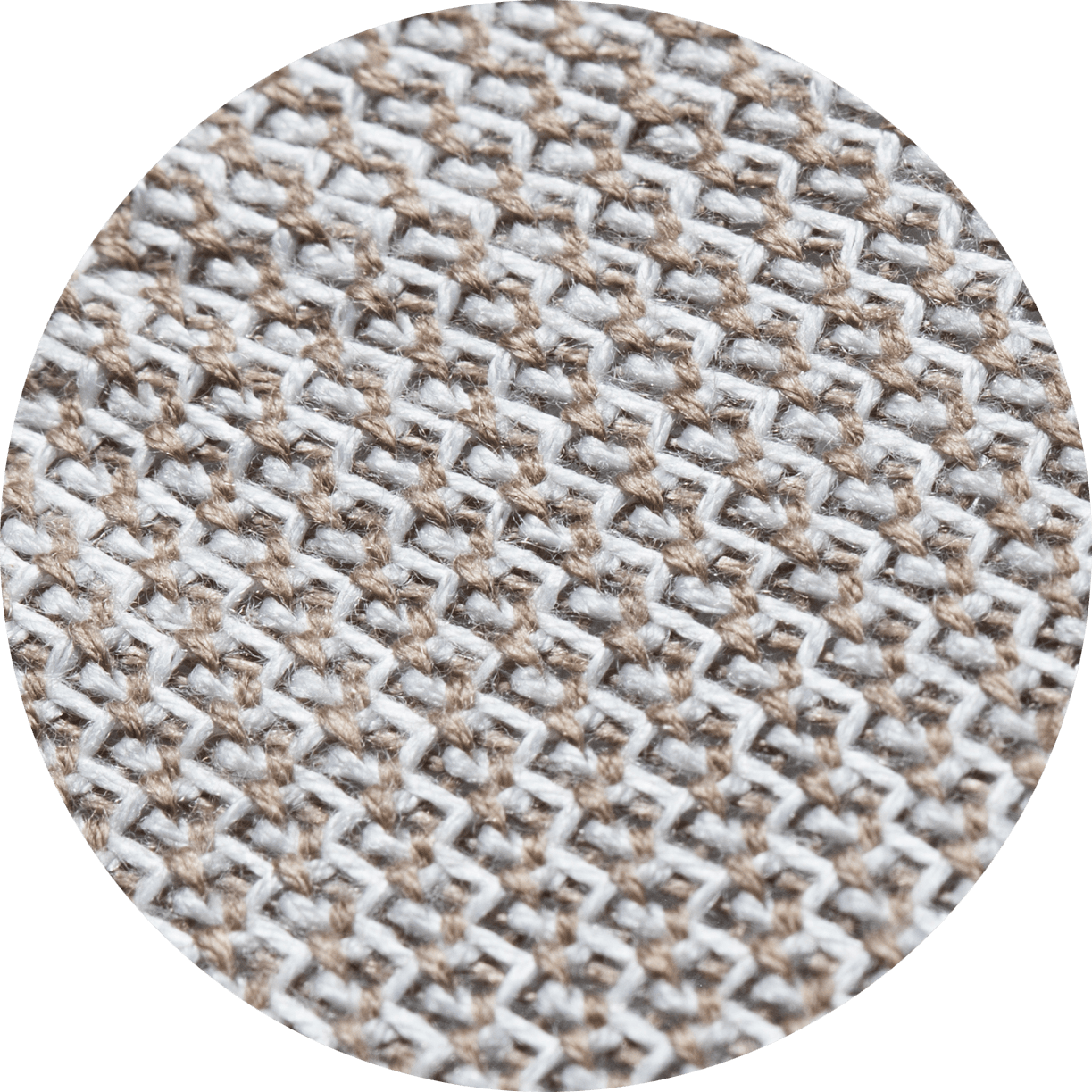

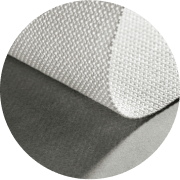

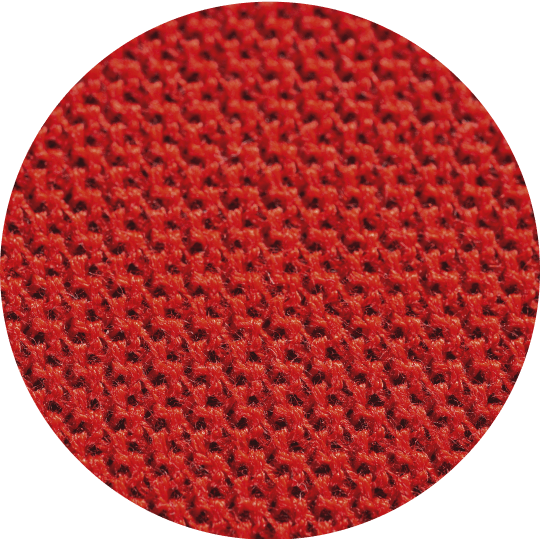

The Aeria1 knit resulted from an inventive process. The initial function of a knitted fabric to allow air to circulate was extended to the acoustic domain to let sound through. Like the generic trademark Frigidaire in the field of refrigeration appliances, Texaa has come to be synonymous with a specific material and acoustic system. In other words, it refers to a sound-transparent fabric (Aeria) that is sufficiently supple and open, combined with an absorber. Extra special attention is paid to this fabric’s pliable, visual and tactile qualities. Its round knit enhances the way it catches light and amplifies the colour, giving the material a texture that appeals to the touch as much as it delights the eye.

Our pride in Texaa is derived from this textile manufacturing mentality. Our industrial equipment, knitting machines, reels, cutting tables and booths for acoustic experimentation make us feel like craftsmen of home-made products. We produce one-off non-standard solutions for places that are all different. The sound-absorbing function needs to be embodied in items and features that have to be designed to be comfortable and pleasant to live with. The primary, ancestral function of a fabric around clothing, covering and decoration is addressed by attending to yarn quality, its thickness and weight, its brittleness and strength, knit type, tight or loose round knit, yarn mix and the uniformity of a dye. All these parameters are continuously monitored. And all sorts of expertise are involved: from materials engineering to setting our knitting machines, from using tweezers to remove lint from the warp beams (handling 300 perfectly evenly spaced yarns in parallel sheets) to monitoring alignment and dye regularity. Together, they strive to make acoustic requirements fit with striking appearance.

Architect and colourist Christine Bernos has been setting the tone in Texaa since 2005. For her, nothing escapes colour, not even black or white. The rational order that she proposes to achieve with a range of colours does not rule out the relativity of sensations and perceptions triggered by any environment, where flavours, colours, textures, aromas and sounds inevitably play their part. This sense-aware approach meets the built world of architects, where materials, volumes, surfaces and the use to which places are put are the main parameters. Designing a new colour range puts all these factors into play.

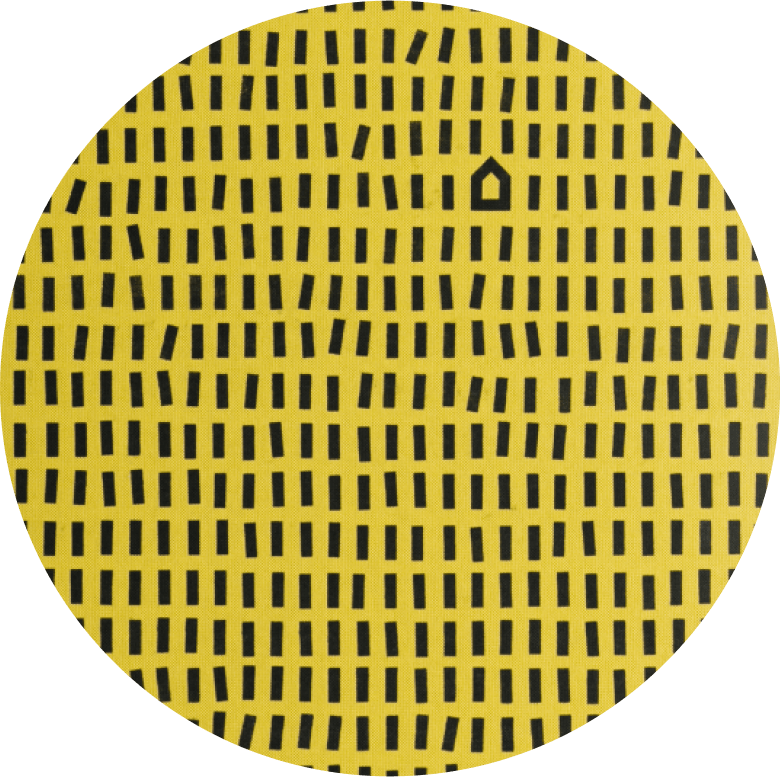

Texaa likes to defend colour. Twenty-six colours and four heathered shades have been selected for the new range. Noticing that grey is often chosen, the colourist designed a range based on the most frequently employed building materials. Wood, glass, metal and stone inspired her to seek gentle, muted tones. Four basic clear-cut colours – yellow, green, red and blue – were associated with a selection of eight shades of grey, ranging from the warmest to the coldest and expressed in dark, medium or light tones. The result is a subtle gradation that allows the colours to slowly emerge as we take time to look at them. This intuitive as well as sensitive choice was based on many samples obtained while toing and froing between yarn manufacturers and dyers. Conceived for architectural purposes, these samples were used to explore how fabrics dyed with the colours in question would appear in different lights against different floors, ceilings and walls. Gradually as discussions expressed uncertainty

or approval of what was new, decisions began to be taken in line with Texaa’s vision and beliefs. The range appears coherent with the dampening effect perceived to exude from it. At this point, the new colours secretly connect users to the relationships between colour and sound, explored by poets and musicians.

1. Texaa resulted from the take-over of an old Bordeaux manufacturer of passementerie or luxury trimmings called Fatexaa, which made pom poms, ribbons and openwork fabrics for slippers and sandals. Aeria is a highly fire-resistant, sound-transparent fabric that is protected from stains, benefitting from an exclusive patent belonging to Texaa, a registered trademark. The specific knit was developed in 1979 with the support of artist Daniel Dartois.

How can I get a quote?

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

How can I order Texaa products?

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

How do I get my products installed?

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

Got a technical question?

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Can I have an appointment?

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Lead times

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

Who should I call?

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

Order tracking

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.