The Palais de l’Alma is a French national palace used by the Presidential Administration, which was built in 1861* and classified as a listed building in 2002. As part of its massive restoration and rehabilitation programme, architects of the Goutal firm used practically the whole gamut of Texaa solutions to solve a tricky conundrum: that of reaching the required surface area for sound absorption recommended by AFL Acoustique, to provide the right level of comfort for users of the building, while protecting the heritage of its unique Napoleonic architecture.

The Palais de l’Alma

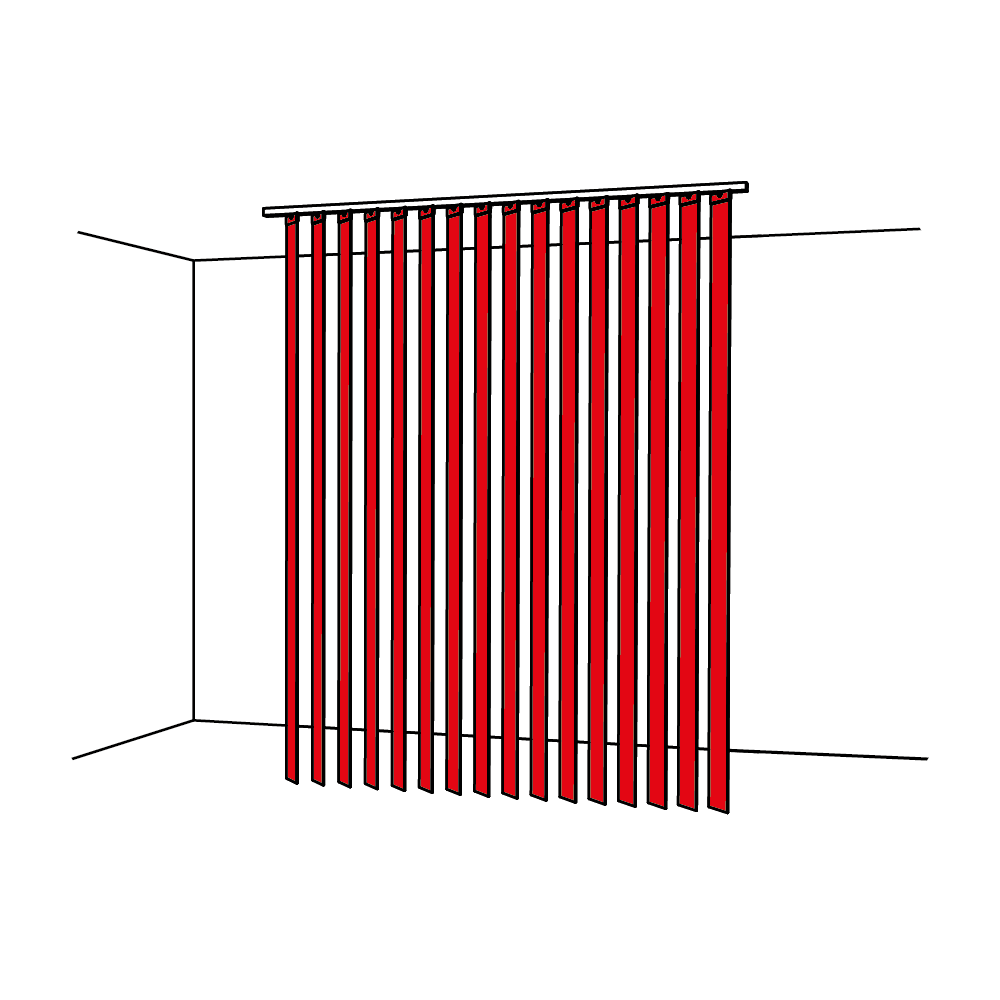

Less than half an hour’s walk from the Élysée Palace, this large-scale rehabilitation project and upgrade to modern standards has been taken on by the architects of Goutal – Architecture et Patrimoine to house French Presidential administrative departments in the former stables of the Palais de l’Alma. The project notably includes the creation of 1,700 square metres (18,300 sq. ft) of office space in the east wing and almost 800 square metres (8,600 sq. ft) for catering services in the west wing. “Within the programme, the open plan offices with a glass ceiling in the east wing and the coworking and restaurant areas in the west wing were sensitive acoustically”, explains Adrien Guillemin, the architect in charge of the project. The challenge in the enormous volumes was to protect the existing architectural features: brick archways with cut stone piers, Napoleon III style columns and cornices with modillions in the east wing, simply restored; and the 1950’s neoclassical decoration in the west wing that the project manager wanted to keep. It was also important to avoid overloading the arches and gain as much surface area as possible for sound absorption, although many ceilings and walls were out of bounds because of the listed building status. To achieve this, the architect relied on the variety of solutions in the Texaa range: Strato acoustic clusters, Vibrasto cladding applied to the furnishings and stretch-fixed to frames on the walls, Vibrasto displays with archive documents printed on them, and nearly 70 red, white and blue Abso Cones suspended in acoustic rows including the lights, reminiscent of the vapour trails of a 14th-July aerial display.

Creative combinations to the west

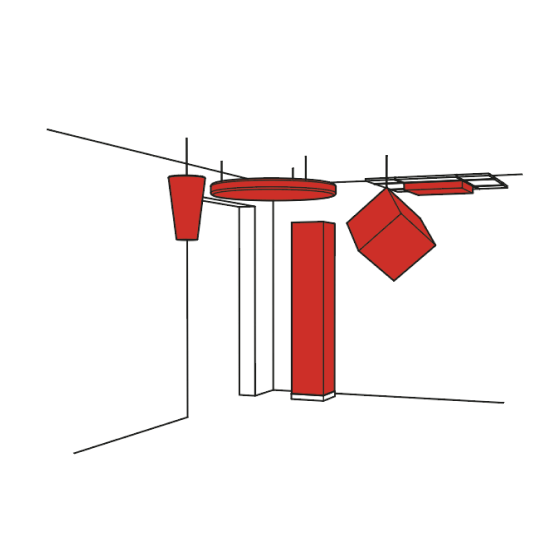

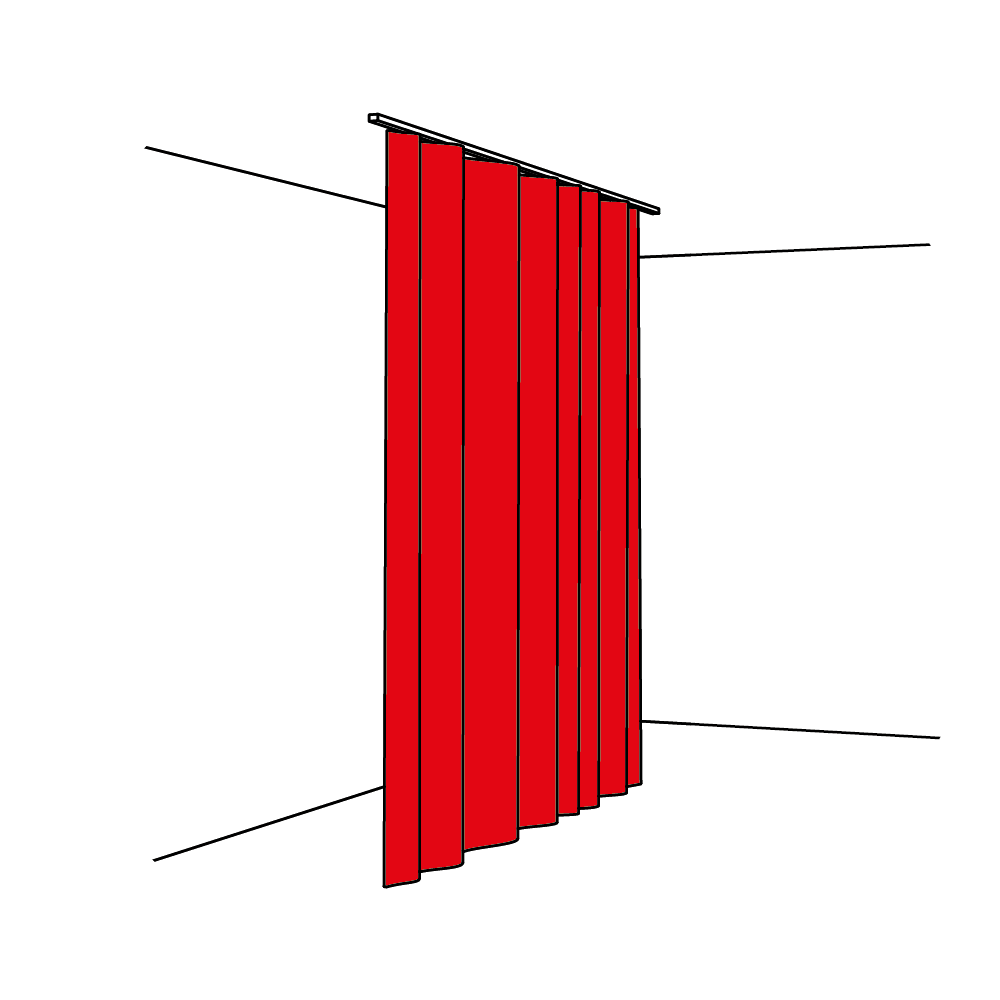

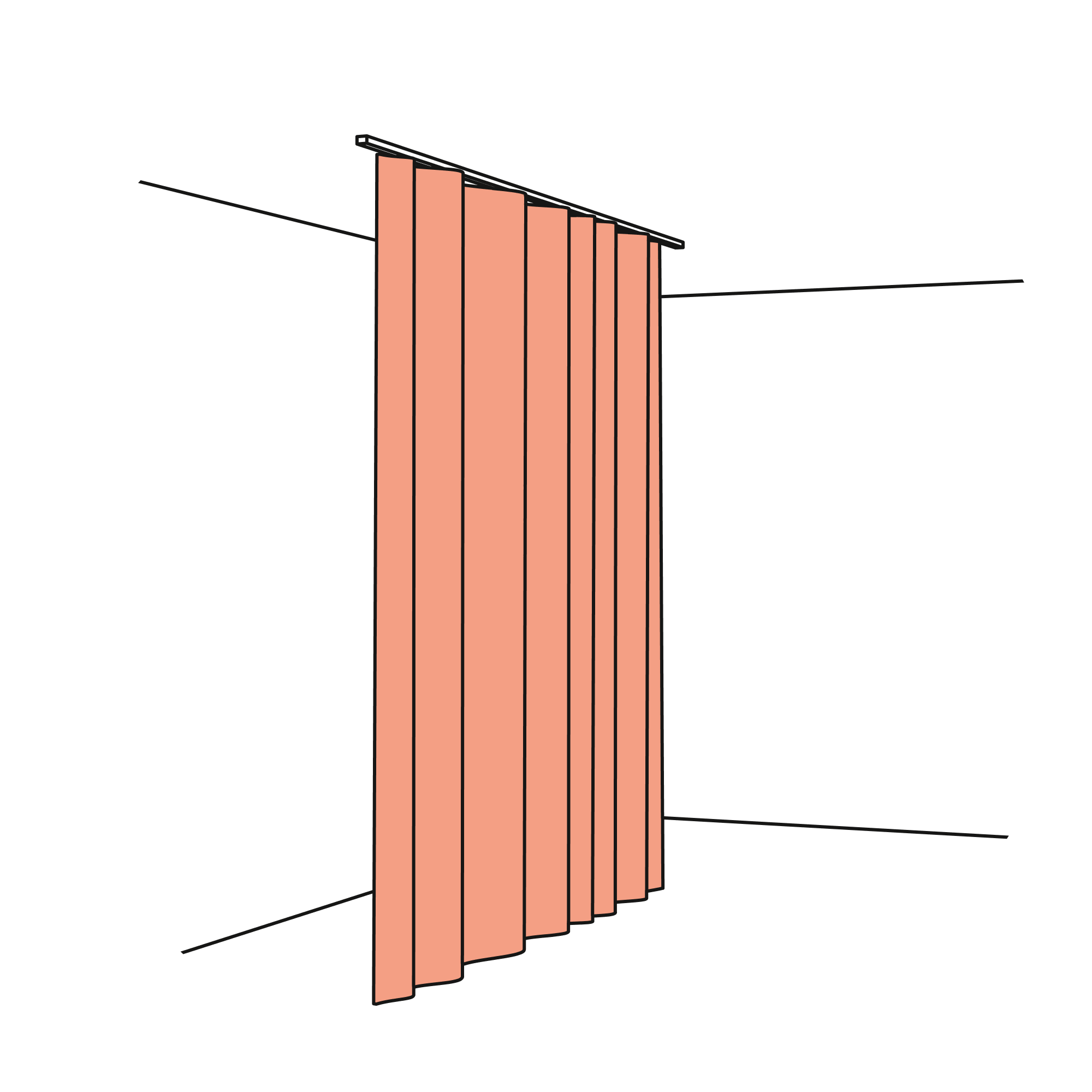

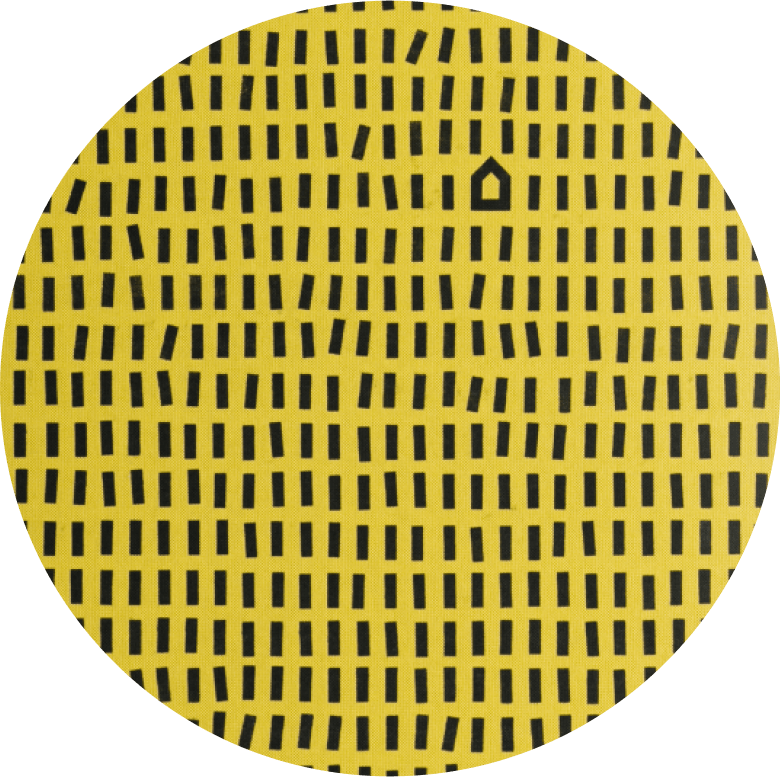

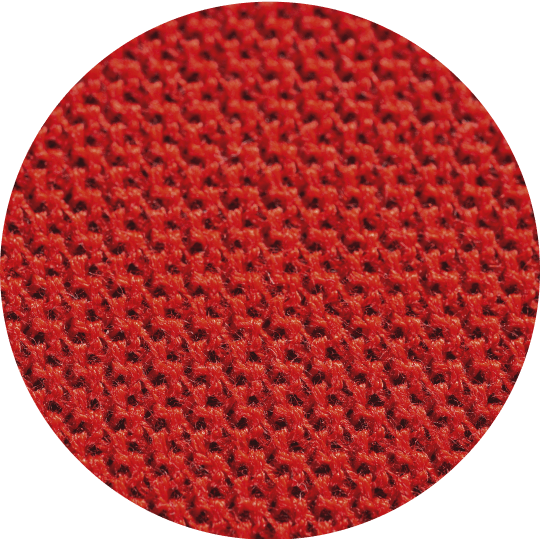

The architect wanted to keep the restaurant area’s 1950’s feel. The challenge was therefore to reach the required surface area for sound absorption to ensure acoustic comfort in this enormous space with its glass roof and walls already adorned with columns and cornices, and studded with many openings. “The ceiling was already completely covered with an acoustic render,” comments Guillemin. “One of the options was to hang acoustic accessories to increase the absorption area, while allowing the light to pass through and slightly lowering the perceived height of the space.” He settled on the choice of using cones from the Abso range to be suspended under the legacy glass roof. To find the correct pattern, he performed a number of 3D simulations, then modelled the shape of a large airship, which he used to position the 68 cones on a frame with two subtle curves, while including hanging lights in the design that were selected to match the cones. The whole composition is suspended on specially designed, extremely fine aluminium netting, which is fixed to the glass roof using a network of small metal cables. “The whole thing is belly-shaped,” explains the designer. “The lowest cone is at the centre of the room and the others hang higher and higher as they approach the outside of the shape, which opens up the view of the large, limed oak doors and the cornices.” The colour choice is a nod to the Presidency. “Back at the office, we call this the 14th of July room!” adds Guillemin with a smile, who is pleasantly surprised how little time it took to hang the cones onto the structure. Nevertheless, still more absorption area needed to be added to reach the objective set by the acoustician. Enter Vibrasto in two roles. “Either side of the glass entrances, we had some wall space available”, continues Guillemin. “And as the project ran its course, I came across some historical documents that charted the building’s original design guidelines, such as the number of horses that the stables were to house and the staff that needed to be lodged, as well as the list of recommended construction materials, corresponding sketches, etc. I had a lot of fun making up collages of these documents, which we had printed on Texaa’s Vibrasto cladding material. We framed these with brass moulding like you would a picture. And we also stretched solid-coloured Vibrasto onto small metal frames and fixed them above some of the doors with a recess strategically placed in the centre to disguise the ventilation grilles. This added a little more absorption area.”

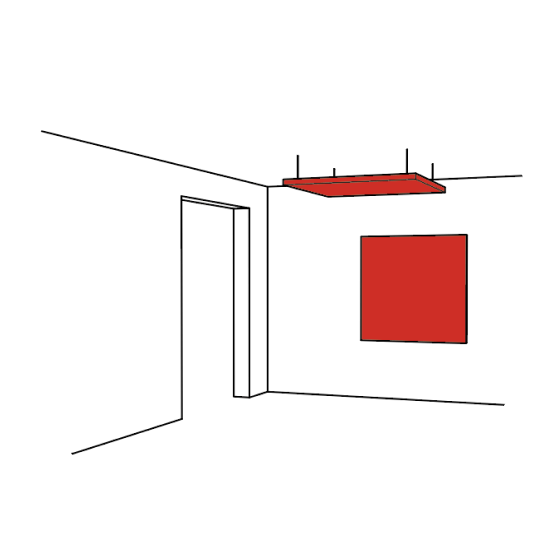

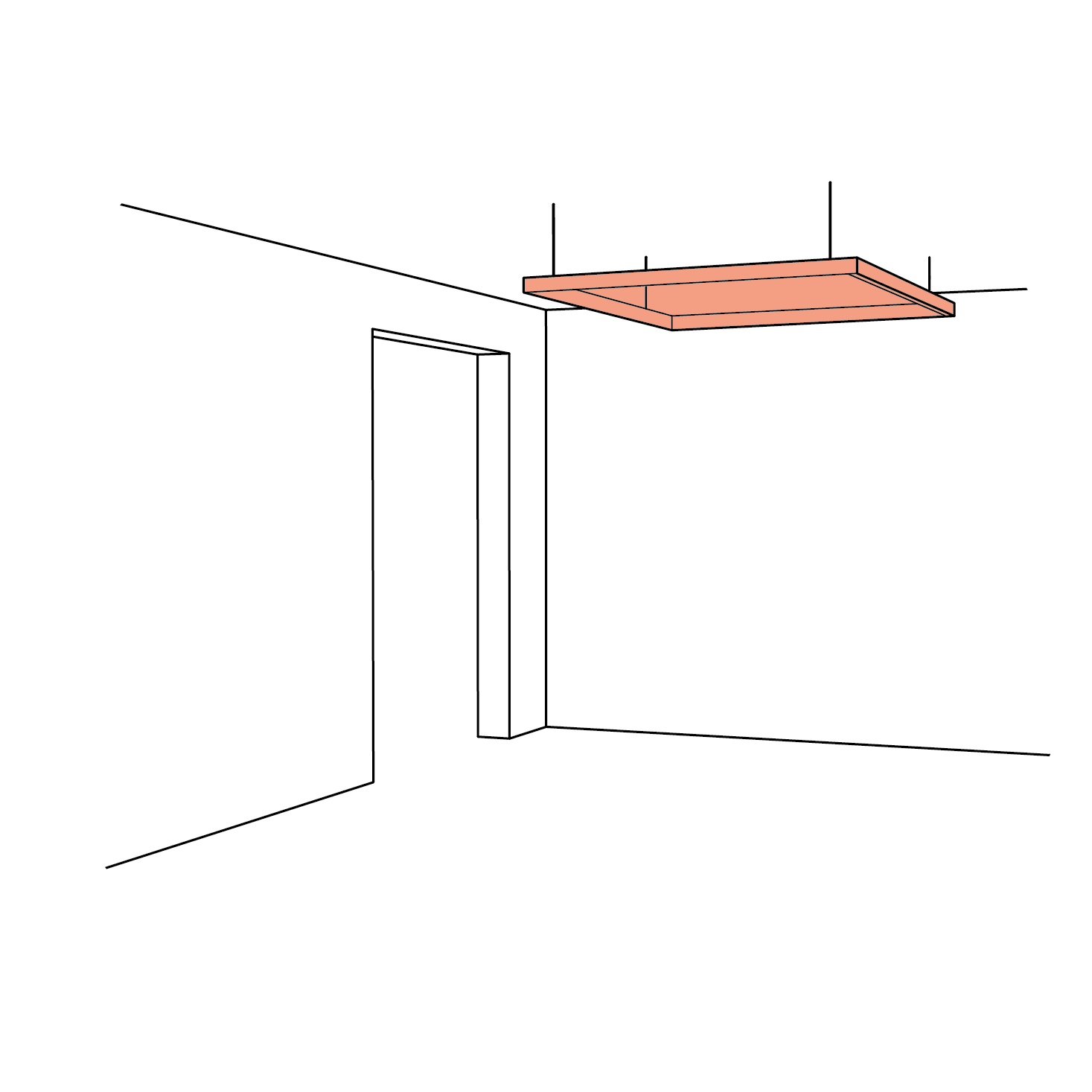

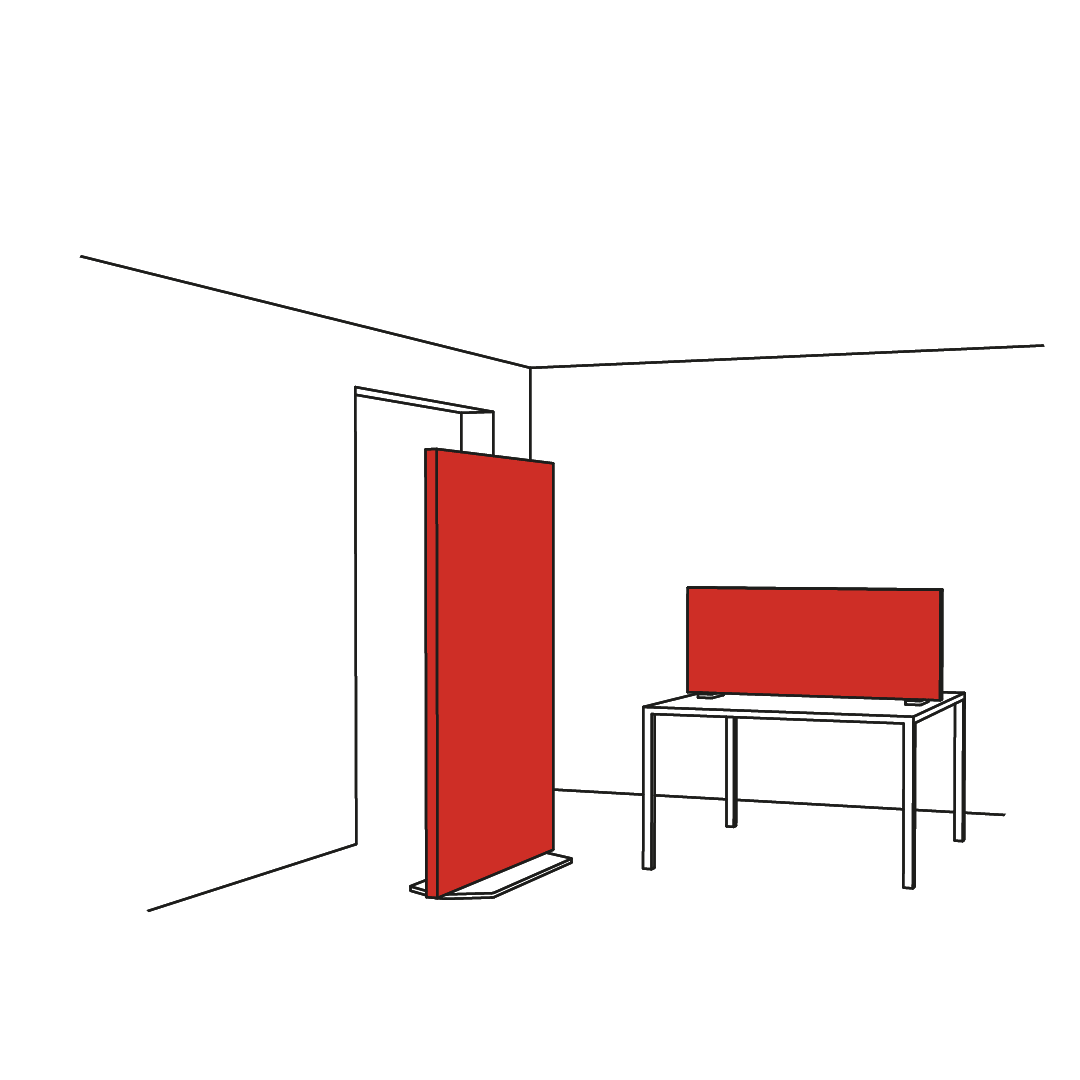

Acoustic porticos

The programme also included a small lounge-like cafeteria and a coworking space. To solve the acoustics issue, the architect designed wooden porticos with Vibrasto cladding on the insides and undersurfaces. “We were able to play with colours here,” says Guillemin. “We obtained support from the Texaa teams to design the details of the finishing moulding and fixings, and we provided this to the joinery firm, which built the porticos. It was all very straightforward to set up.”

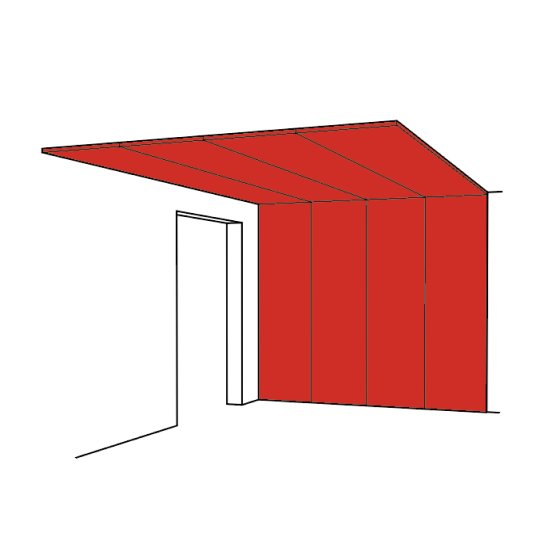

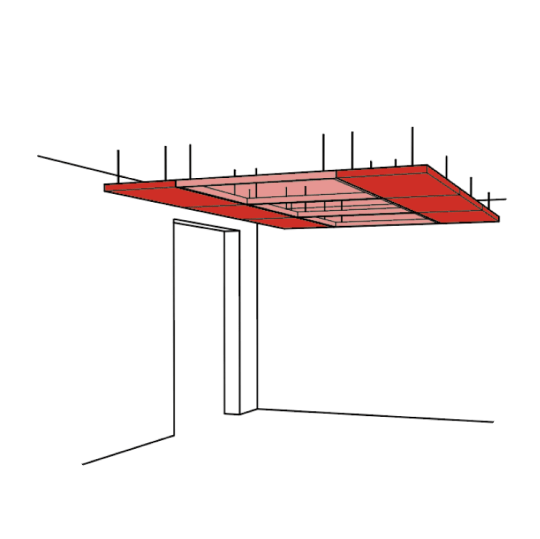

Acoustic cluster to the east

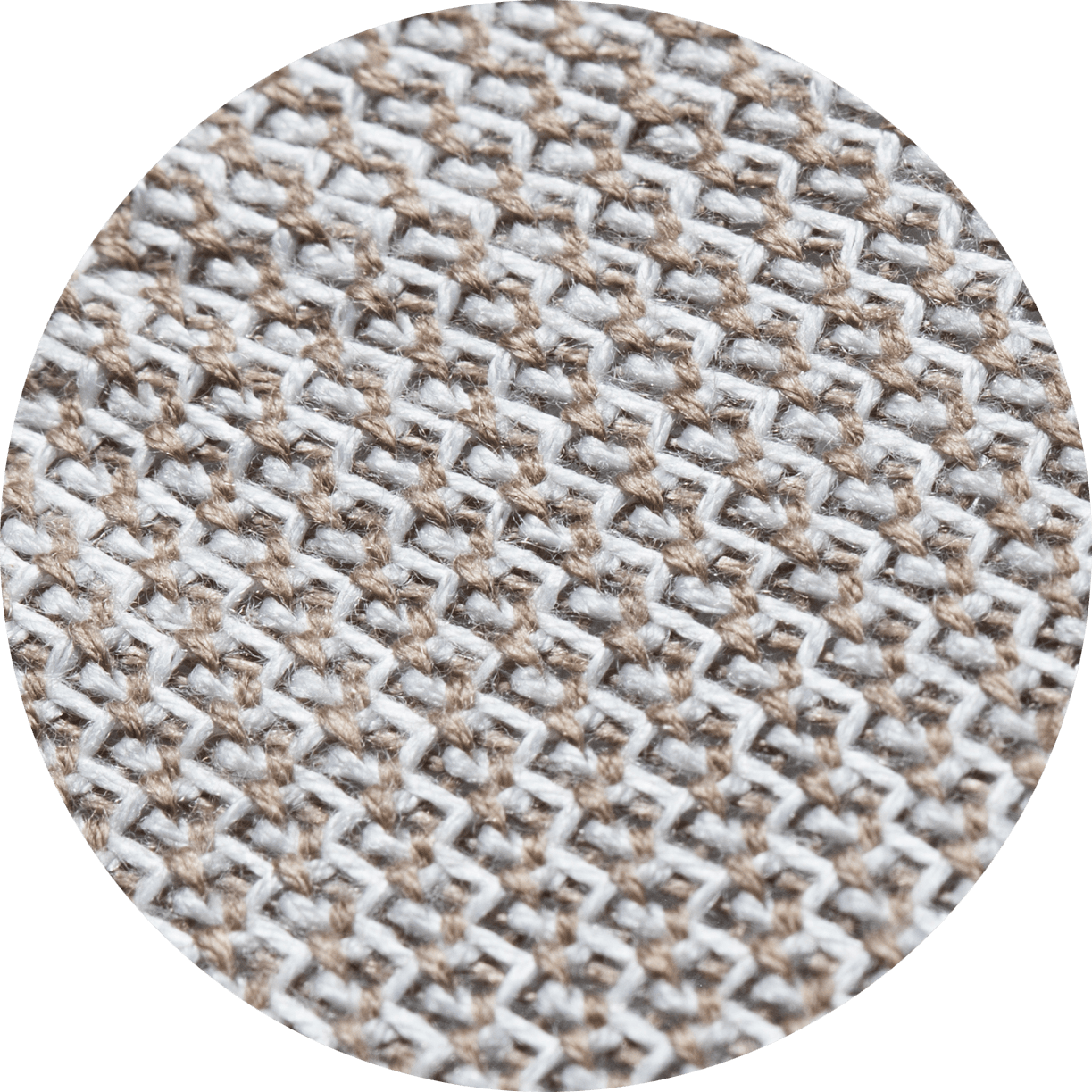

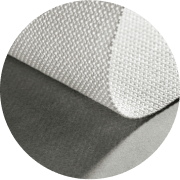

In the central aisle of the open plan area in the east wing, which covers almost 1,700 square metres (18,300 sq. ft) of workspace, the Strato cluster on the ceiling provides both a technical and aesthetically pleasing solution. “This large volume consists of big brick arches with coffer ceilings between each supporting beam,” points out Guillemin. “We restored the arches with a very fine acoustic render, so as to avoid adding weight, but we needed more absorption surface area to provide the necessary comfort for the users of the two blocks of offices either side of the central aisle. And we had to achieve this with minimal modification of the original building. The Strato cluster enabled us to do it, while hiding the cables and ducts running along the ceiling, as well as making it possible to install diffuse lighting down the middle of the space, which is also a walkway.” The ceiling was also given added interest with a subtle range of textures by alternating the open and closed stitches of the fabrics that were chosen in two complementary neutral colours.

* In 1861, the architect Jacques-Martin Tétaz was made responsible for the building of new stables for the household of Emperor Napoleon III. The buildings of this “Palais de l’Alma”, named after the 1854 battle in the Crimea, were transferred to the Presidency of the French Republic in 1881, and from 1888 housed the Presidential stables. During the 20th century, its wings, partially repurposed in the 1950’s, housed different organisations – the National Weather Forecasting Office and the Magistrates’ High Council – until from now on they accommodate the administrative departments of the Presidency.

Project name: Rehabilitation and upgrade of the east and west wings of the Palais de l’Alma

Year to be delivered: 2021

Town-city / Country: Paris, France

Project owner or contracting authority: The French Presidency

Contractor: Agence Goutal – Architecture et Patrimoine

Acoustician: AFL Acoustique

Photographer: Sergio Grazia

Are our products fire-resistant?

Yes, our products are fire-resistant and comply with regulations governing public-access buildings.

Texaa solutions are tested for reaction to fire in accordance with international standards. Fire reaction test reports (fire certificates) are available upon request to support specification.

Please feel free to contact us by email at cf@texaa.co.uk or by phone at +44 (0) 20 7092 3435.

How can I get a quote?

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

How can I order Texaa products?

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

How do I get my products installed?

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

Got a technical question?

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Can I have an appointment?

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Lead times

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

Who should I call?

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

Order tracking

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.