There is no other project like it: the first leisure “spaceport” located in the middle of the Nevada desert, one of the unique places on earth that is not flown over by commercial airlines. Designed by architects Foster + Partners, Spaceport Virgin Galactic was gradually erected on arid ground, as a slightly dramatic beacon for amateur astronauts promising them an equally unique experience.

Spaceport America

A central vertical structure cuts through the whole edifice from the spacecraft hangar via the simulation area and other spaces, ending up in the lounge with its large, glazed wall. This space is equipped for living and working and offers a breathtaking view of the runway, which serves as a gateway to space for lucky patrons. London architects Viewport Studio, who are familiar with Virgin’s brand DNA (after designing Boeing 787 and Airbus A330 interiors for Virgin Atlantic), took on the singular challenge of designing the interior of this completely new type of airport with its enormous floor area of nearly 600 sq. m (6,460 sq. ft) and double-storey ceilings, where a catering area on the ground floor coexists with an open coworking space on the first floor and the operations centre.

Togetherness

Designer Gautier Pelegrin of Viewport Studio explains: “The apprentice astronauts don’t just come and take their spacecraft like they would board a plane. They stay for a while with their family and the professional astronauts, who train them for their flight. All this could be quite stressful, and it is essential for everyone to feel they are all part of the same team. This was primarily what Virgin Galactic requested regarding the layout of the common areas: people had to feel they were together. We had to provide for a teambuilding experience, which removed the differences between customers and staff, making them colleagues engaged in achieving the same goal, the success of the mission in a way. And all this had to be comfortable and pleasant.” All furniture and fittings were custom-designed, and the colours and textures were inspired by the natural environment: the colour of dark desert rock on the ground floor becoming white on the first floor evoking the sky’s burning light.

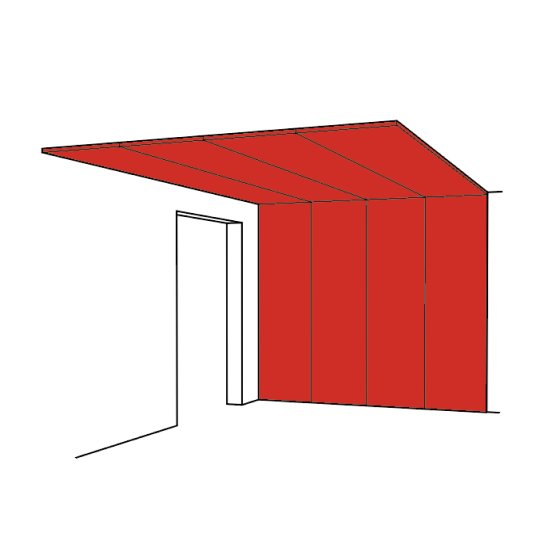

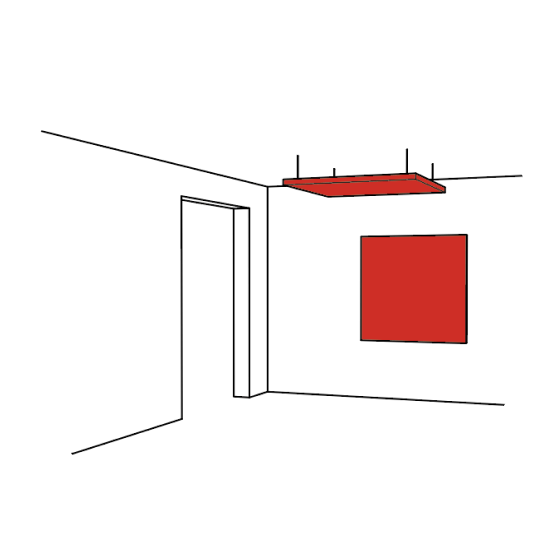

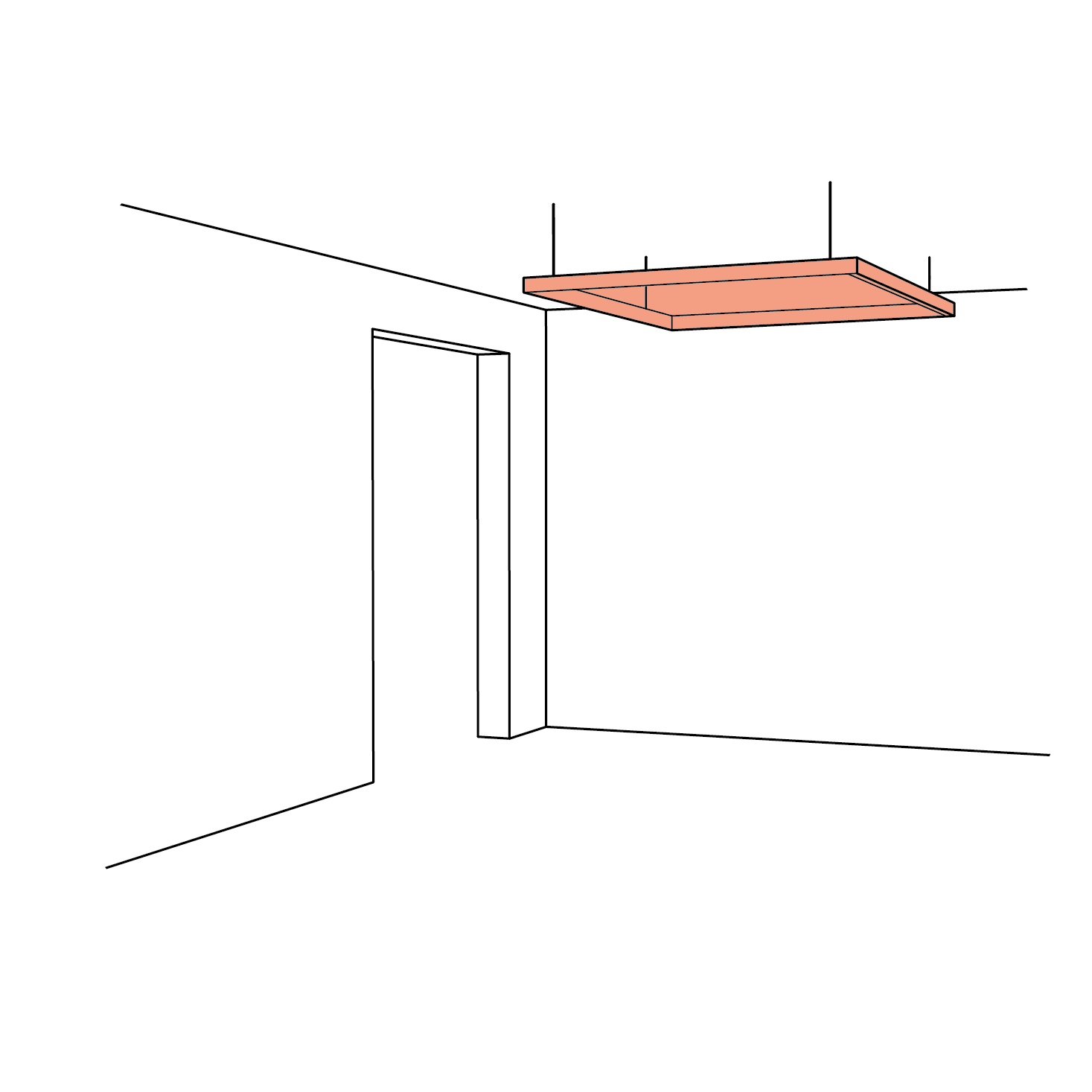

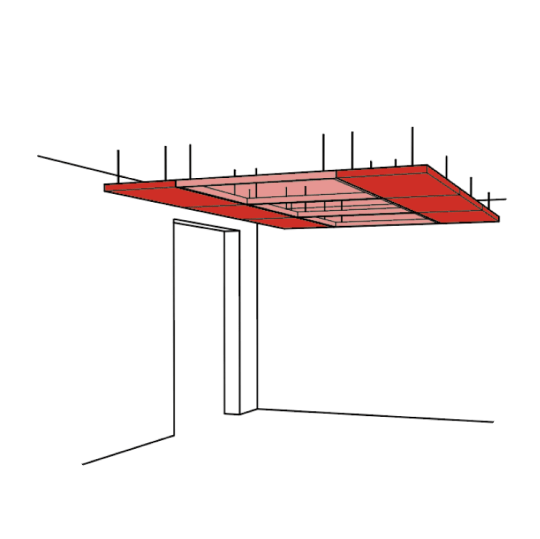

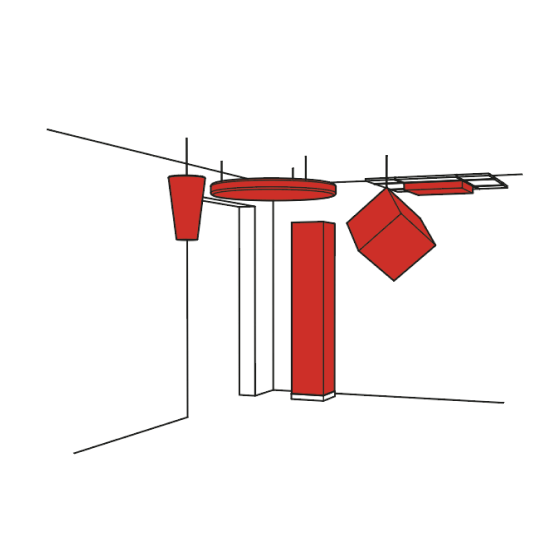

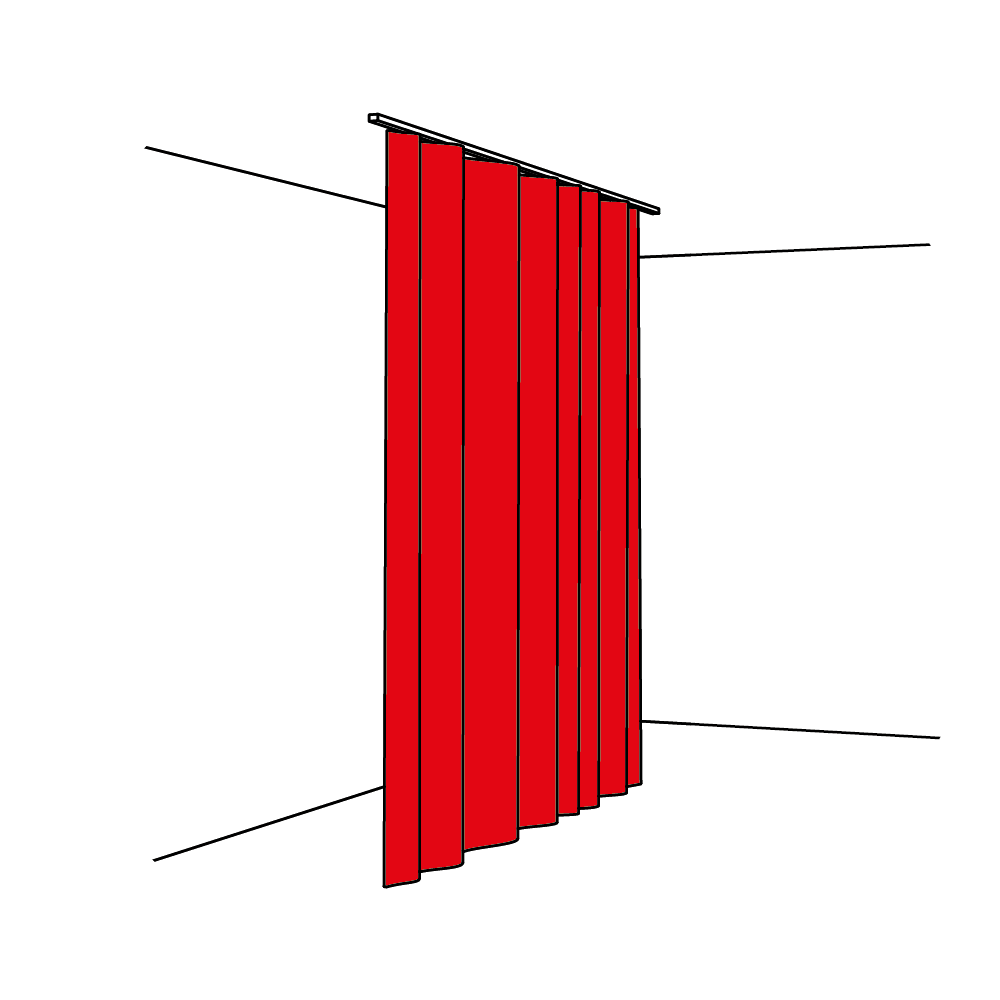

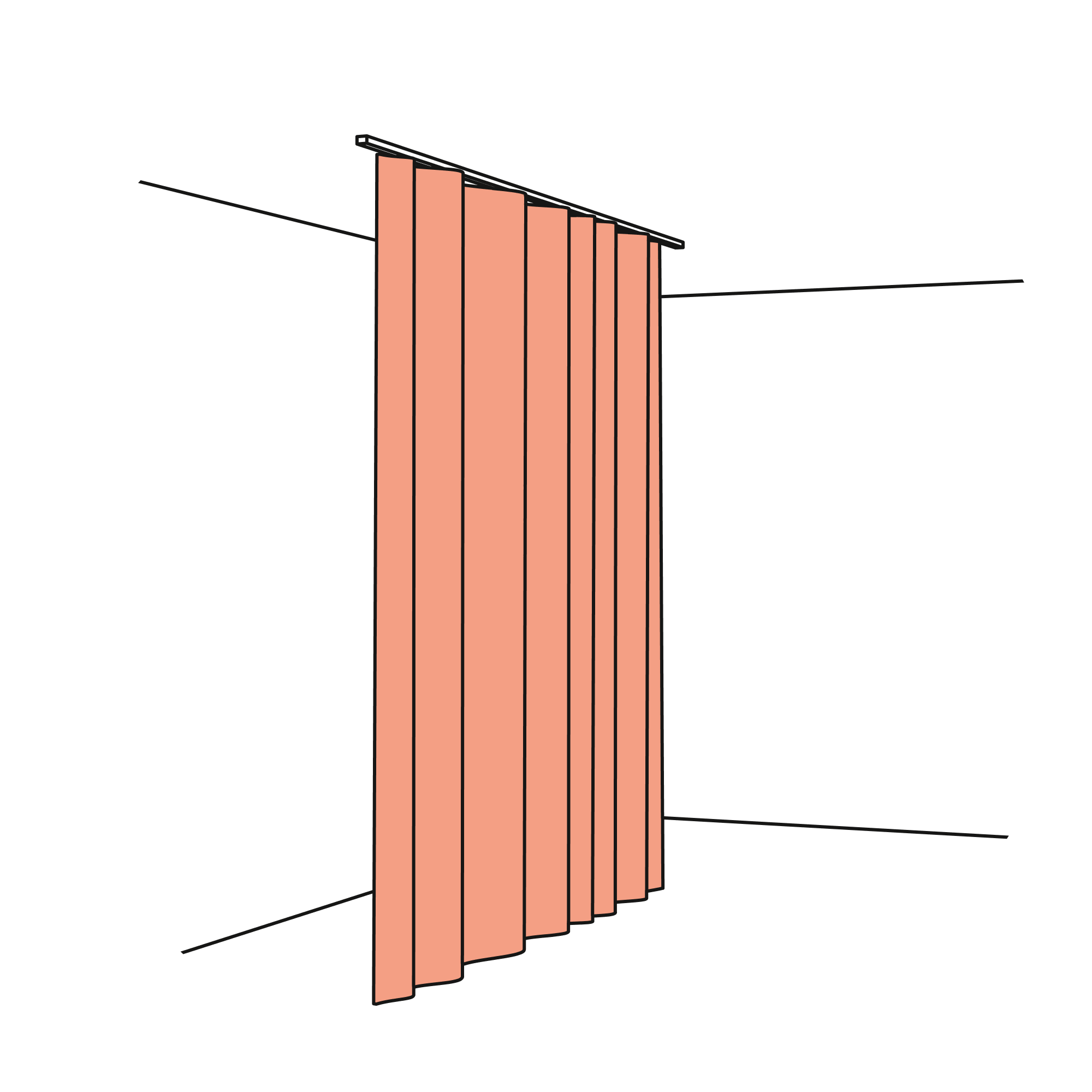

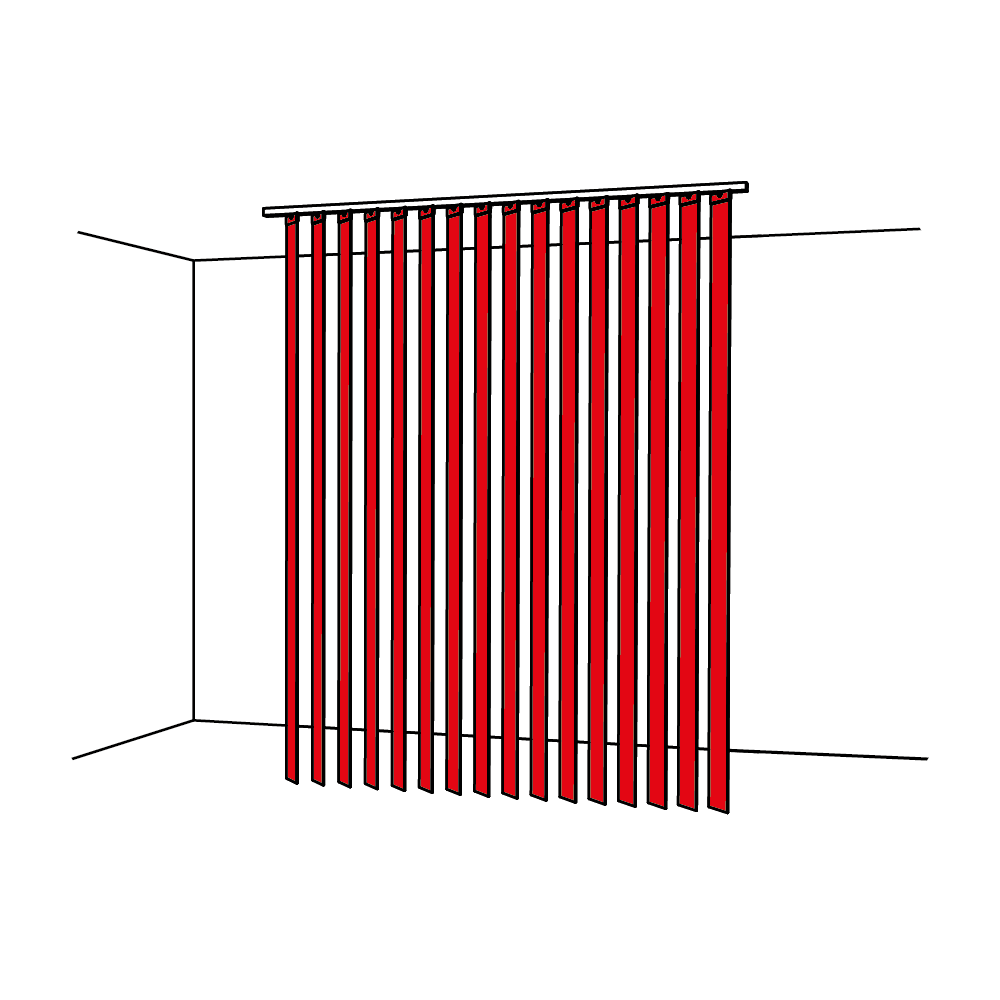

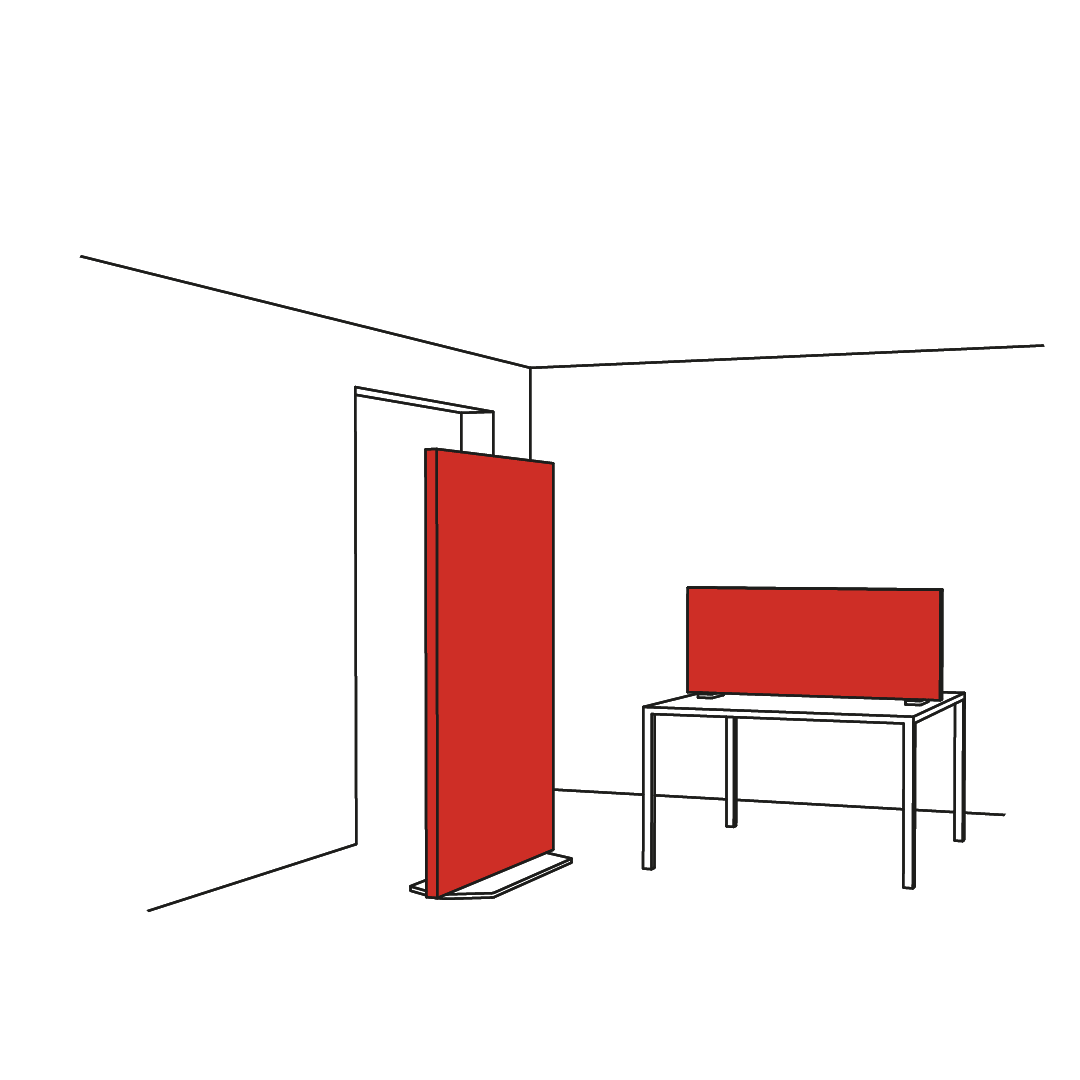

Absorbing sound waves

Enormous open spaces create acoustic challenges, especially here where there is only one immense wall located at the back. Pelegrin continues, “The building is a kind of rotunda with completely blind operations rooms and the control centre in the middle. The large common area is laid out around the central section in a circular segment. We installed sound-absorbing materials in slatted panels on the back wall and the mezzanine railings. The natural wood finish attenuates as it rises in the building, becoming thinner, white-painted slats above. To improve the sound absorbing qualities further, the interior architects turned to Texaa solutions. “The performance of the materials was really important in this project”, says the designer. In the open-space coworking area on the first floor that adjoins the control tower, wide mother-of-pearl-coloured Stereo and Stereo Air panels are fixed to the ceiling, while Vibrasto acoustic cladding of the same colour has been applied to the wall. “With the control tower so close, this solution made it possible to contain the sound reverberation so that operations staff are not bothered”, he goes on. “Because the flight operators work very close to each other. They need to be able to communicate verbally or non-verbally in milliseconds. And there is very little light so that the screens’ visibility is not compromised.” Inside the control room, Stereo acoustic panels are suspended in rows, tilted towards the screens with strip lighting between, providing the necessary acoustic comfort to enable absolute concentration. Prepare for take-off!

Project name: Spaceport Virgin Galactic

Year to be delivered: 2020

Town-city / Country: Las Cruces in the New Mexican desert, USA

Project owner or contracting authority: Virgin Galactic

Contractor: Foster + Partners (building architects) & Viewport Studio (interior design)

Photographer: Robin Zielinski

Are our products fire-resistant?

Yes, our products are fire-resistant and comply with regulations governing public-access buildings.

Texaa solutions are tested for reaction to fire in accordance with international standards. Fire reaction test reports (fire certificates) are available upon request to support specification.

Please feel free to contact us by email at cf@texaa.co.uk or by phone at +44 (0) 20 7092 3435.

How can I get a quote?

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

How can I order Texaa products?

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

How do I get my products installed?

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

Got a technical question?

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Can I have an appointment?

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Lead times

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

Who should I call?

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

Order tracking

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.