Our environmental responsibility policy

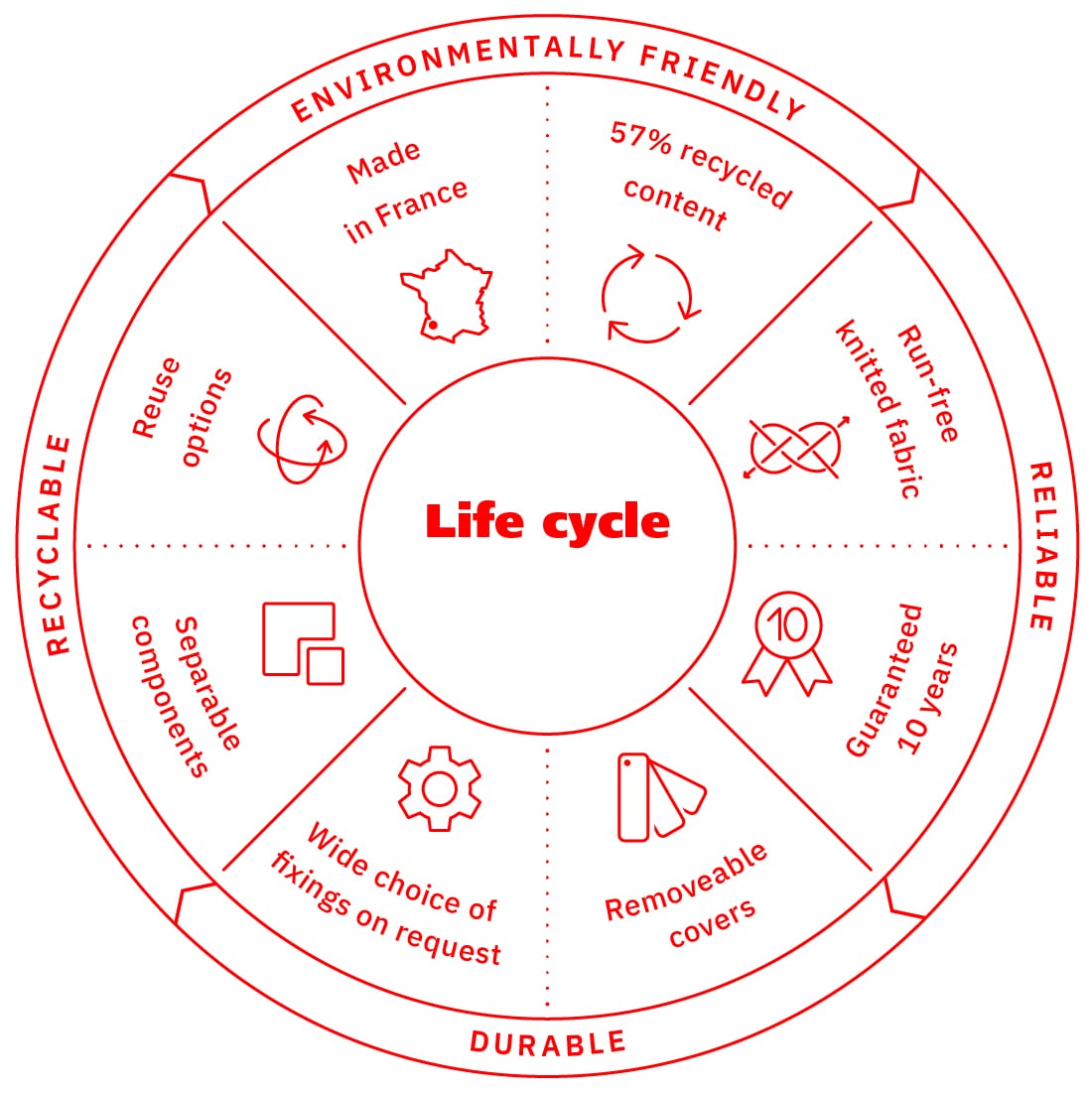

To provide a positive contribution to architecture, Texaa strives to make its products long-lasting and reusable, while reducing its impact on health and the environment.

To provide a positive contribution to architecture, Texaa strives to make its products long-lasting and reusable, while reducing its impact on health and the environment.

The process used to knit the Aeria fabric, which covers our acoustic devices, was selected to ensure hard-wearing products that last over time :

— Run-resistant: a hole in the fabric will not get larger

— Easy maintenance: antistatic 7.1010 Ω (EN 1149-1)

— Abrasion resistance: NF EN ISO 12947-2 (30,000 Martindale test cycles)

— Colour fastness graded equal to or higher than 5 on the ISO 105 B02 scale

— IMO (International Maritime Organisation) certification for our maritime applications

Our sound-absorbing components do not deteriorate over time: the materials used are rotproof and insensitive to weather conditions.

Texaa panels and objects are fitted with removable covers, enabling product reconditioning to be carried out several years after their installation, while keeping the original acoustic components. This type of operation can be performed on site. In this way, Texaa has carried out many reconditioning operations either directly or through its professional partners.

Servicing Texaa acoustic solutions

After several years of development, the proportion of recycled materials that make up all our Vibrasto acoustic cladding products has recently reached almost 60% on average (based on 2023 sales).

In its Stereo acoustic panels, Texaa uses fully recycled sound-absorbing material, and the proportion of recycled materials has reached 57% of the total value of these products.

The sound-absorbing material used in our Kora screens is 90% recycled.

Texaa uses wooden components as much as possible to replace steel or aluminium parts. Local pine is offered as an option for some of the feet of our Kora acoustic screens. This is also the case for some of the Strato ceiling accessories.

Furthermore, a version of the Aeria fabric entirely made of linen, is now available as an alternative, and can be used for certain types of project.

Texaa demonstrates awareness of its environmental responsibility with its craft-based production model, organised to ensure quality, but also to reduce its carbon footprint.

— All Texaa products are manufactured exclusively in France in our Gradignan workshop outside Bordeaux.

— Texaa has always privileged suppliers, who are also partners, who we want to be close to, and who are therefore located in France or Europe

Texaa fournit toutes les données utiles :

— carbon footprint measurements per square metre of each solution, derived from the complete life-cycle analysis of each product, supplied in EPDs in the French format of a fiche de déclaration environnementale et sanitaire.

— also carbon footprint data calculated per unit of absorption to enable the comparison of one solution against another. This data takes into account the footprint per square metre of interior space to be acoustically enhanced (rather than per square metre of product), and varies according to the different solutions in our range, as the example below demonstrates.

From a health standpoint, all Texaa products release very low volatile organic compound (VOC) emissions and undergo testing in line with current regulatory requirements. The antistatic qualities of our Aeria fabric significantly reduce the attraction and accumulation of dust, thus creating a healthier living environment.

In our assembly processes, we use water-based adhesives or other bonding technologies (and not solvent-based glues).

We use materials that are intrinsically fireproof (without using fireproofing additives that could escape from the materials over time). Since our components are stable, their fire safety remains constant throughout the product’s entire life. This makes them compliant with regulations governing buildings receiving the public.

Labels and certifications:

— Our Stereo panels first received an A+ Air Label Score and were deemed compliant with the German AgBB protocol in 2011. Our other solutions progressively obtained the same level of certification, and the whole range has been certified since 2018.

— In 2021, Aeria for marine applications was awarded IMO (International Maritime Organisation) certification, which is based on International Fire Code testing methods, and covers all merchant vessels and pleasure boats.

Metal, plastic and cardboard waste is sorted and collected by a specialist supplier, who recycles it through existing channels.

Furthermore, since Texaa only works exclusively to order, we do not produce unsold or obsolete product, which would end up as waste.

Yes, our products are fire-resistant and comply with regulations governing public-access buildings.

Texaa solutions are tested for reaction to fire in accordance with international standards. Fire reaction test reports (fire certificates) are available upon request to support specification.

Please feel free to contact us by email at cf@texaa.co.uk or by phone at +44 (0) 20 7092 3435.

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.