To service your Texaa products, it is all about sustainability, and the enjoyment of having well-made things that you take care of, even 20 years later. Grégoire Comby, responsible for Texaa sales in New Aquitaine, tells us more.

Servicing – easy routines for better sustainability

Grégoire, tell us about servicing.

It’s all about sustainability! For Texaa, servicing and sustainability are two sides of the same coin. What I observe across all the projects I deliver (and that’s a lot in 30 years [smiling]), is how well the products last over time. The vast majority are really easy to service or refurbish. But what I see as important too, is the idea of something being shared with links and relationships being developed over time between the former and present owners of the premises, our customers and the architects. There’s a sense of awareness and handing things down too.

Can you tell us more?

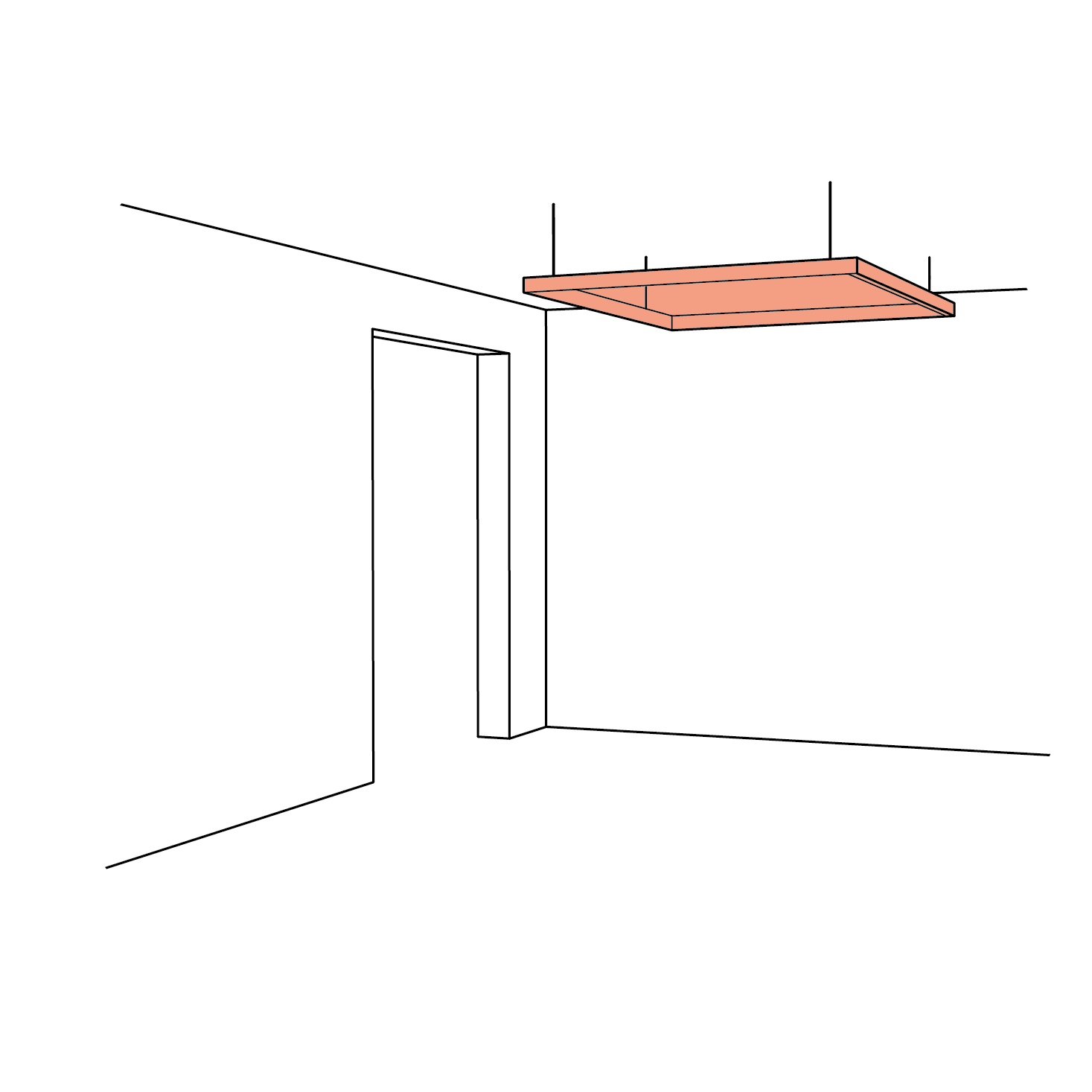

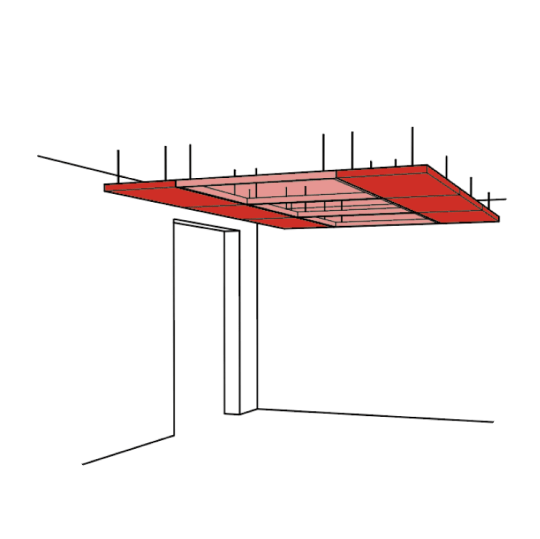

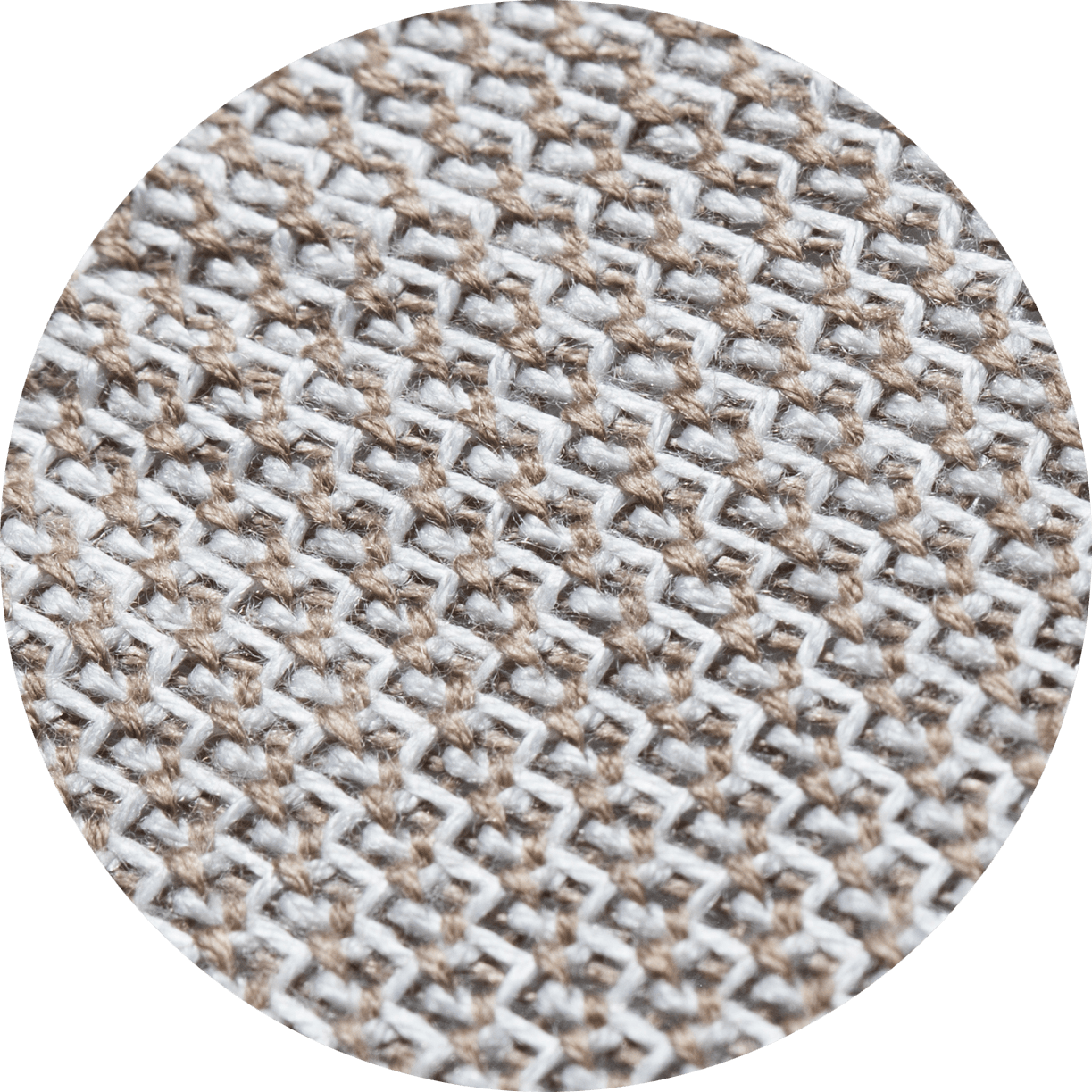

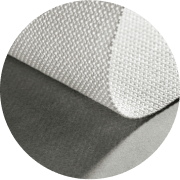

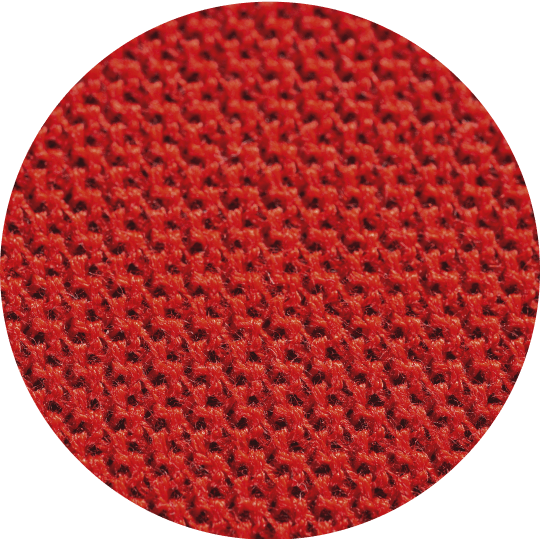

Here’s a very concrete example: in 2006, we installed a Strato acoustic ceiling in the Gradignan media library very close to our workshop. This year, so nearly 20 years later, the library manager called me, because he had to replace the air conditioning motor, and he needed to get access to the equipment above the ceiling. To avoid any damage during the maintenance work, he asked us if we could come and temporarily dismantle the ceiling installed in one of the rooms, before the air-conditioning engineer arrived. I went to the library with a colleague and in less than an hour the job was done. It was a great opportunity for us to see how the ceiling looked two decades after its installation: to identify what might have deteriorated over time and what might have needed replacing. But apart from a little dust on the top of the panels, nothing had aged! The fabric had not lost its elasticity or colour in an area with lots of windows, where temperature and ultraviolet light levels vary significantly. The sound absorbing material was also intact. And the frames too. Even the relative lack of dust was surprising, but this is one of the advantages of our Strato ceilings: air circulates, so there is not too much accumulation, and the texture of the materials prevents dirt from becoming encrusted. So after dismantling, we took the opportunity to vacuum clean everything from the fabric covers to the sound absorbing wadding. And when the maintenance work in the roof space was complete, we reinstalled the ceiling as if it were brand new, straight from our workshop! It’s always a pleasure to go back to a previous worksite, to see that what we took great care in designing, manufacturing and installing, has stood the test of time, ten or even twenty years later. For us, every worksite is a prototype, a special project, something unique that is made to last. We are proud of what is produced in our workshop, because we put our hearts and souls, and our expertise into it. We always hope that it will last for a long time, or a very long time!

You were talking about refurbishment. Is that also part of servicing?

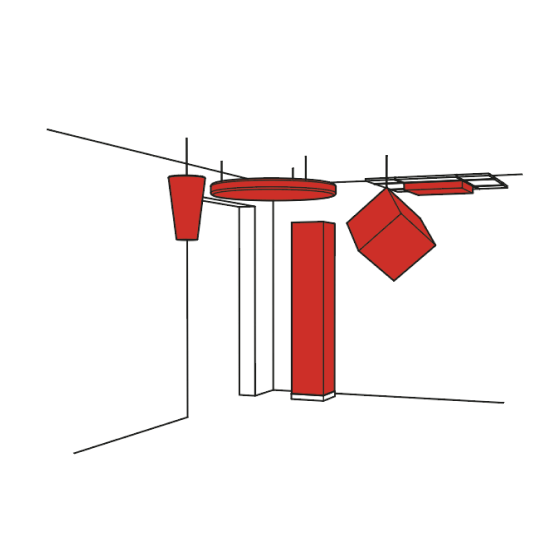

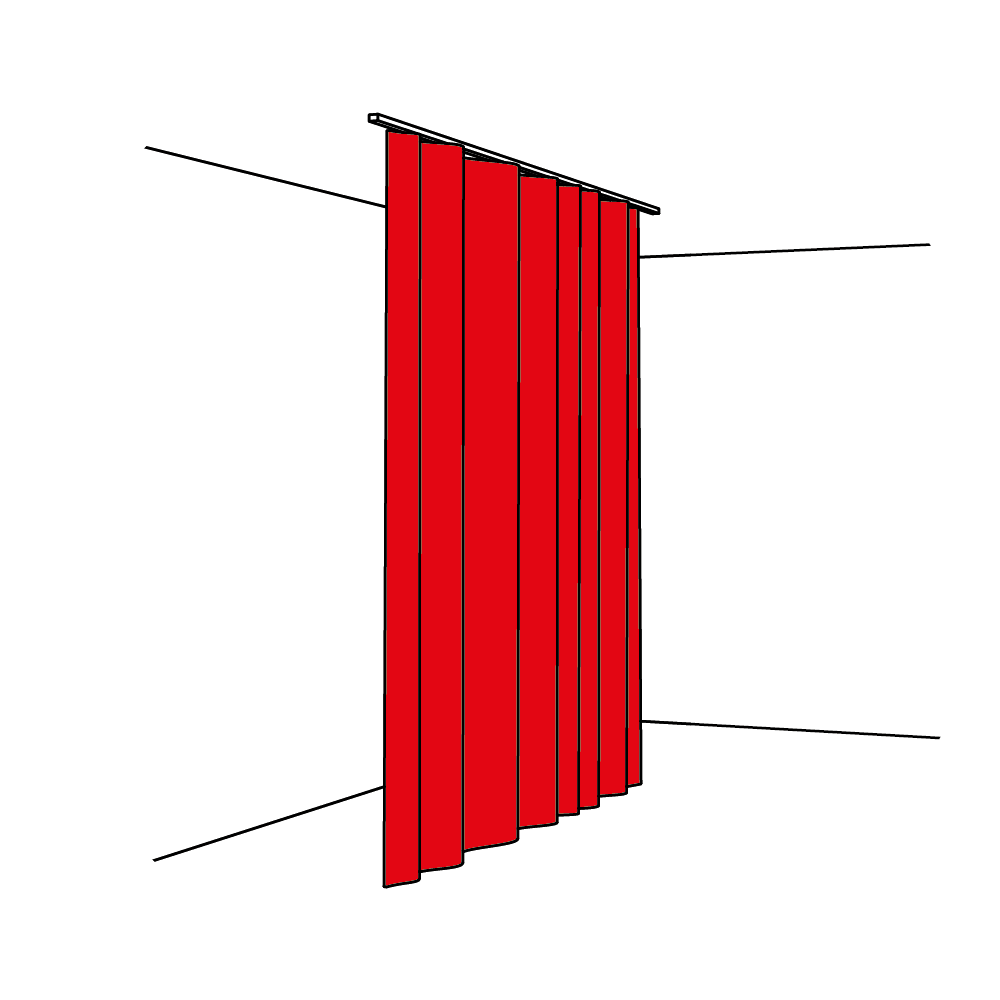

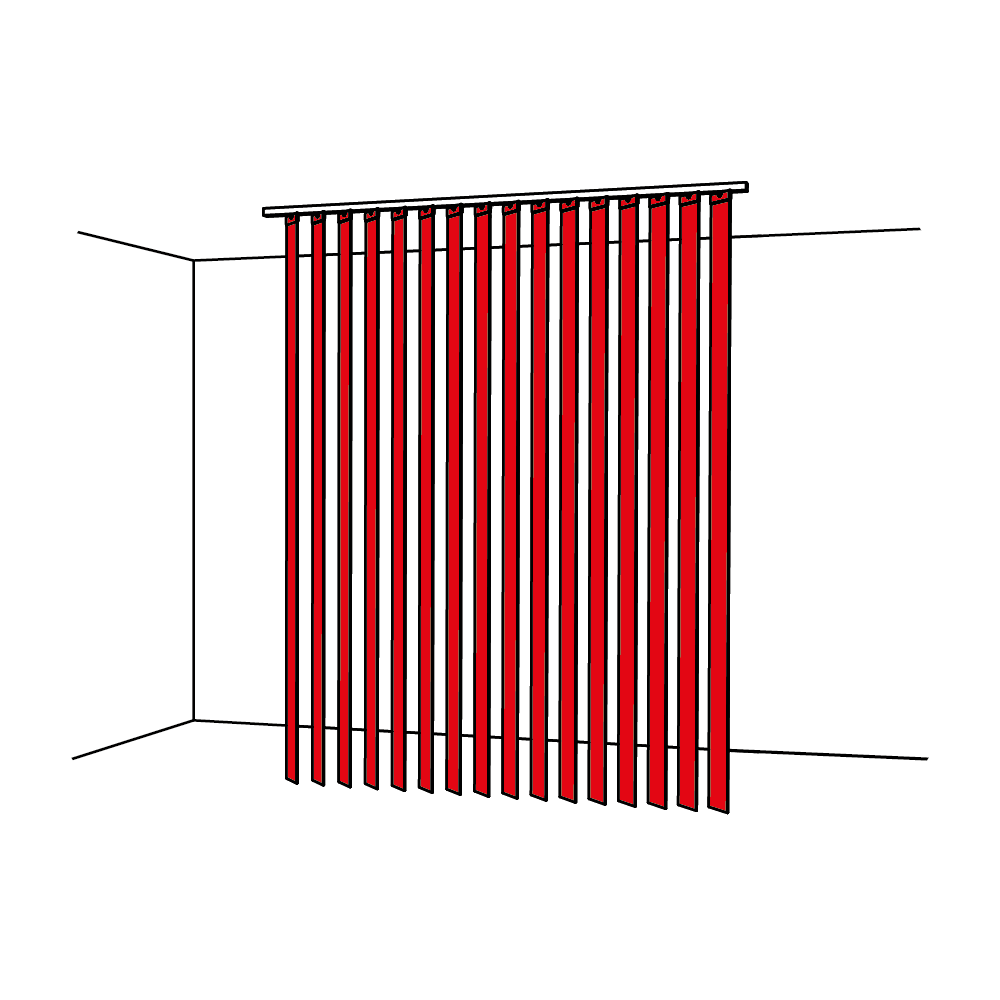

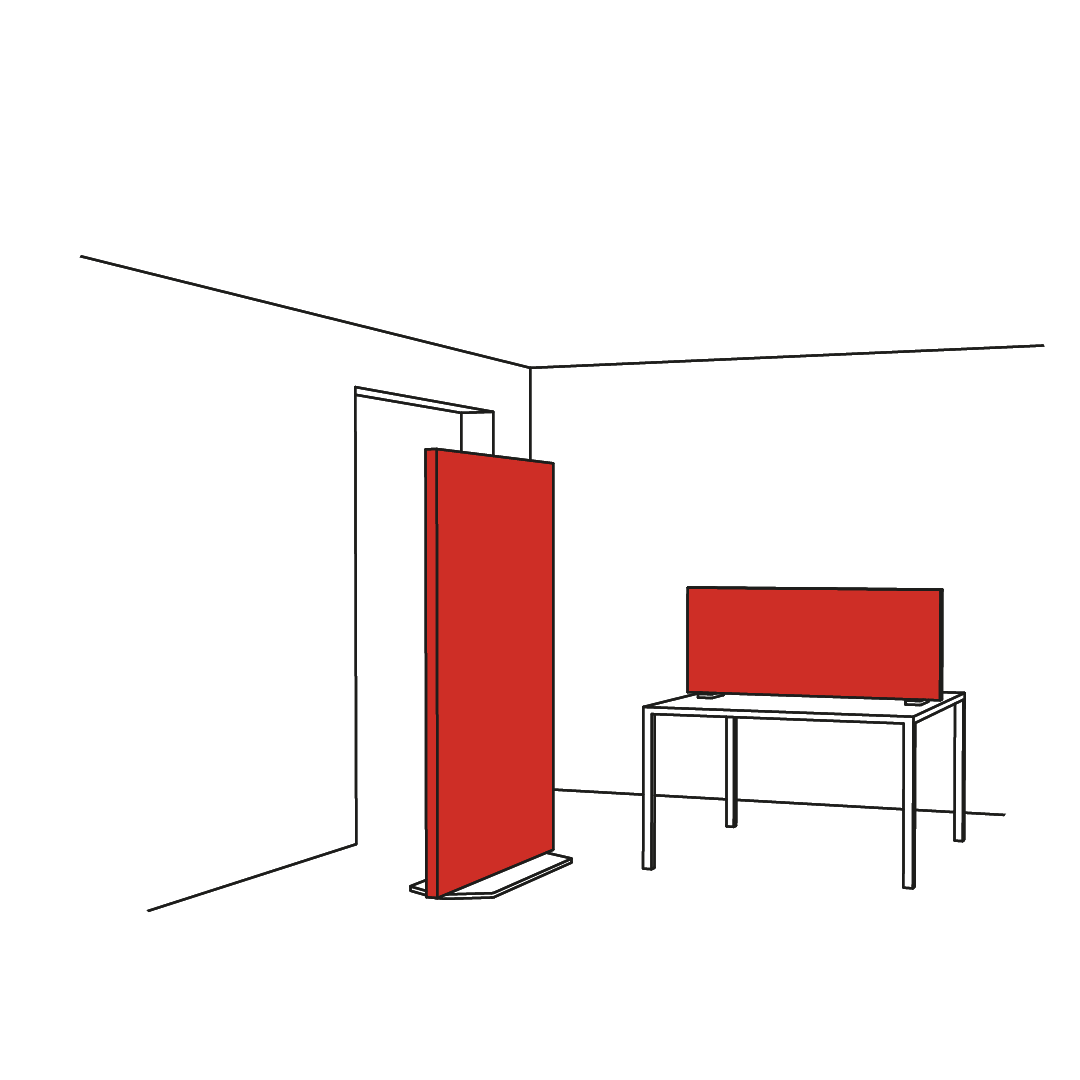

Yes, because the goal is to extend the useful life of our products to a maximum. Again, some worksites demand a lot of effort, design capacity and installation time to get the right result. So we always try to find the best solution to refurbish or develop existing installations. We’ve been doing this for more than 40 years. We know our trade perfectly. And there again, there is a range of possible solutions, depending on clients’ requirements and project constraints. Refurbishment can involve changing certain components. if we are working on a system that is already installed. We might want to modify the layout of an existing ceiling, hang certain ceiling panels on the wall, or vice versa, or just change the colours, etc. We design, manufacture and supervise installation, of course, but we also offer advice, so that what has been installed in the recent or distant past, lasts at least as long again! Just recently, the new owners of a restaurant in Bordeaux asked us about colours. Grey Stereo panels had been installed long ago, but black was more suited to the new design they were proposing. Since everything was in great shape and working well, and suited the space available, it would have been a pity to replace it all. So we recommended they changed the covers. In the same way, unused fabric stocks can be used to extend the useful life of an old installation. It happened recently on an old worksite, a school where large ceiling islands had been installed to create a patchwork effect. The school wanted to fill in the mosaic with a specific colour, but it was only a few panels, and we had a very similar colour in our old catalogue. It wouldn’t have made sense financially, technically or environmentally to develop a new colour and produce a run of fabric specifically. We also have a small stock of reconditioned fabric (from returned orders or expo exhibits); small buffer quantities, immediately available, to offer customers, when their budget is a little tight, for example. Apart from that, our products are manufactured on demand. Servicing, refurbishment and adaptable products are really all about sharing and building connections over time.

Any conclusion?

Our workshop is located in a winegrowing area. There are parallels with wine and the enjoyment of tasting something that has aged well! Or the pleasure an upholsterer has in renovating an old handmade armchair that is handed down from generation to generation. We make acoustic absorption products, but the feeling is exactly the same.

Are our products fire-resistant?

Yes, our products are fire-resistant and comply with regulations governing public-access buildings.

Texaa solutions are tested for reaction to fire in accordance with international standards. Fire reaction test reports (fire certificates) are available upon request to support specification.

Please feel free to contact us by email at cf@texaa.co.uk or by phone at +44 (0) 20 7092 3435.

How can I get a quote?

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

How can I order Texaa products?

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

How do I get my products installed?

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

Got a technical question?

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Can I have an appointment?

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Lead times

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

Who should I call?

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

Order tracking

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.