We are convinced that developing reuse is one relevant concrete response to the environmental challenges of the construction sector. We are organising internal processes to facilitate reuse, but we are keen to integrate them into a wider ecosystem through various collaborative ventures and partnerships with all available professions: architects, all categories of designers, public organisations, reuse specialists, etc.

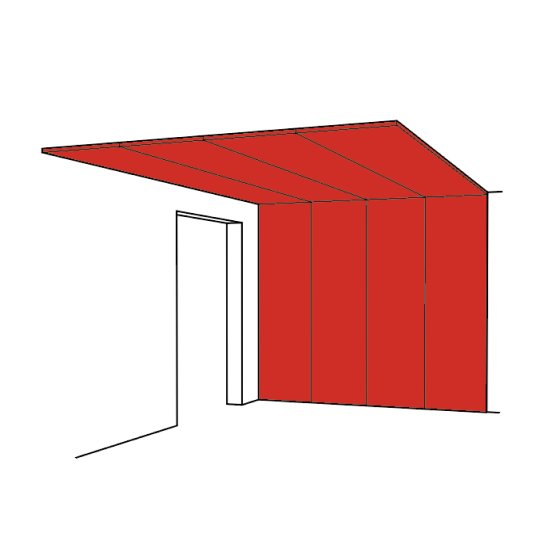

Reuse – how it works

“Our objective is a large-scale change”, explains the CEO of Texaa Matthieu Demptos, “beyond onsite refurbishment of our products or local resale, which we are doing regularly, but still too modestly. We need to progress faster than that.” Thus, doing very concrete things together with different players in the construction and design industries, architectural or not, are exciting ways to learn and set up real, effective circularity projects. After an innovative initiative with Made in Past, a reuse specialist in the selective dismantling and resale of equipment and materials in Lyon, we carried out a massive reuse operation with our Stereo panels, when CFAO Group moved its Head Office in the Paris area. We were also delighted to support REFAIR, a project led by ‘La Fab” (La Fabrique de Bordeaux Métropole) with the Cancan Collective (the project’s reuse consultancy) that aims to create a living platform for the reuse of building materials in the Bordeaux city area. The centre is at the Reuse Base, the former salesroom of the Bordeaux Bed Company, repurposed in 2023 with the help of architect Orianne Scourzic, who was a Cancan Collective member at the time.

Case study

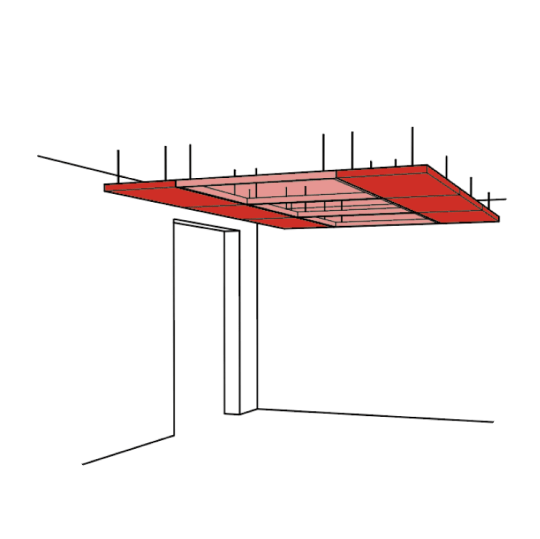

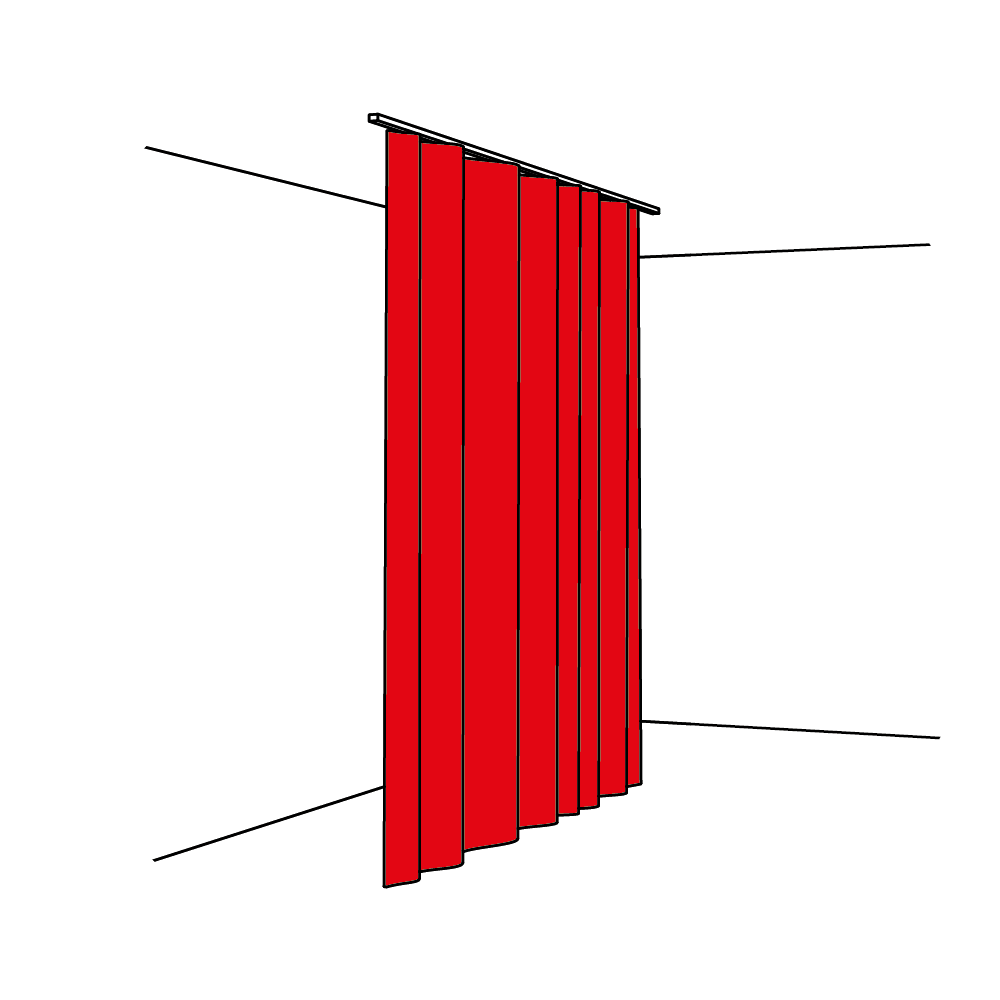

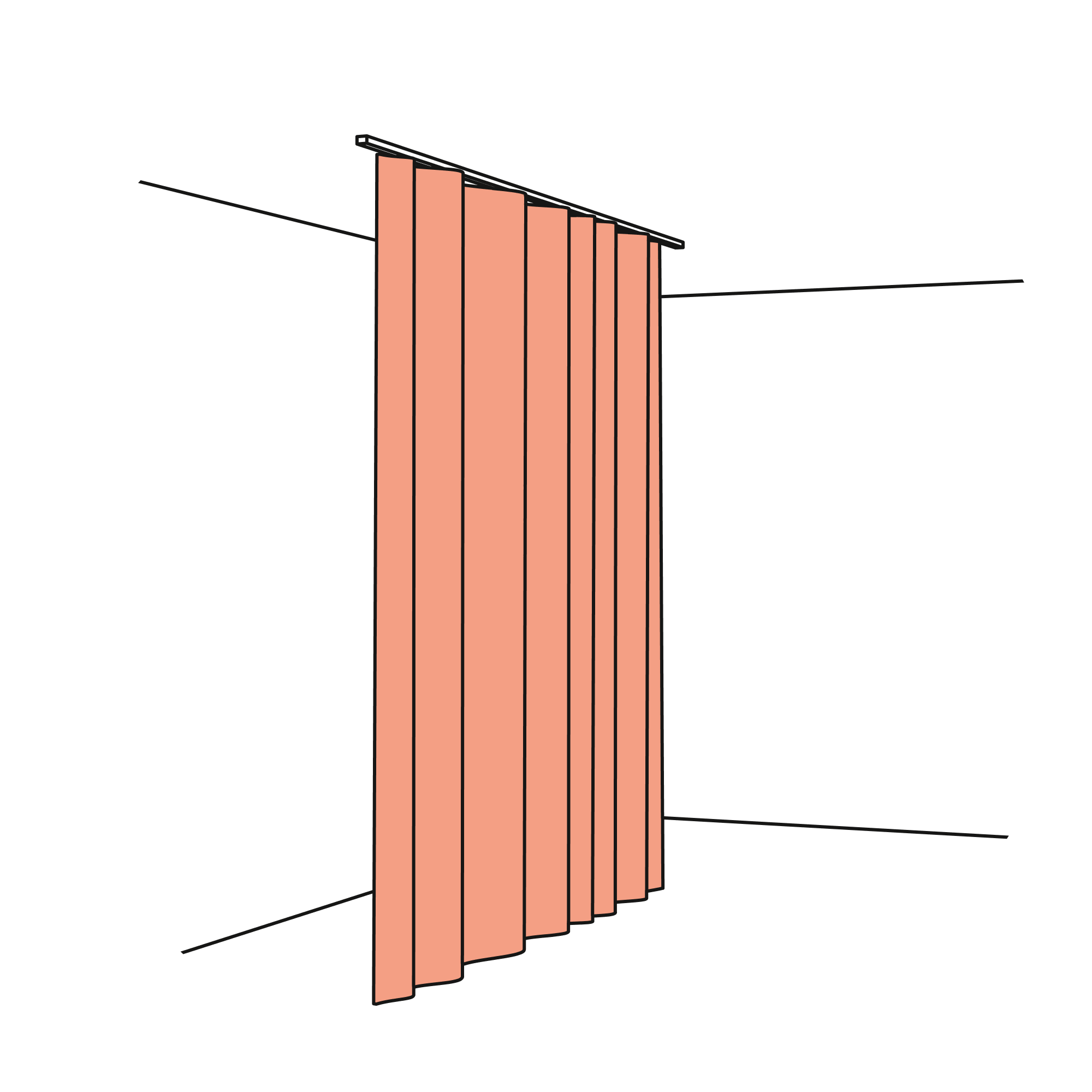

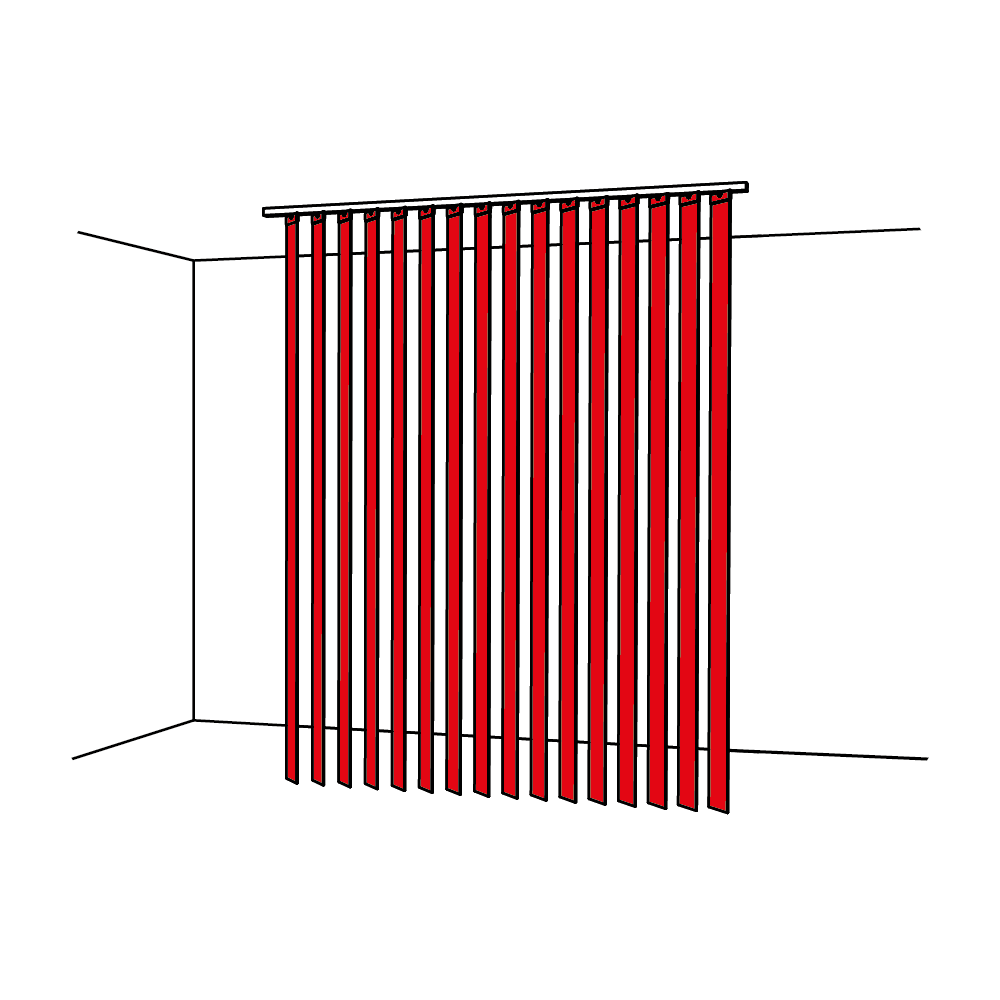

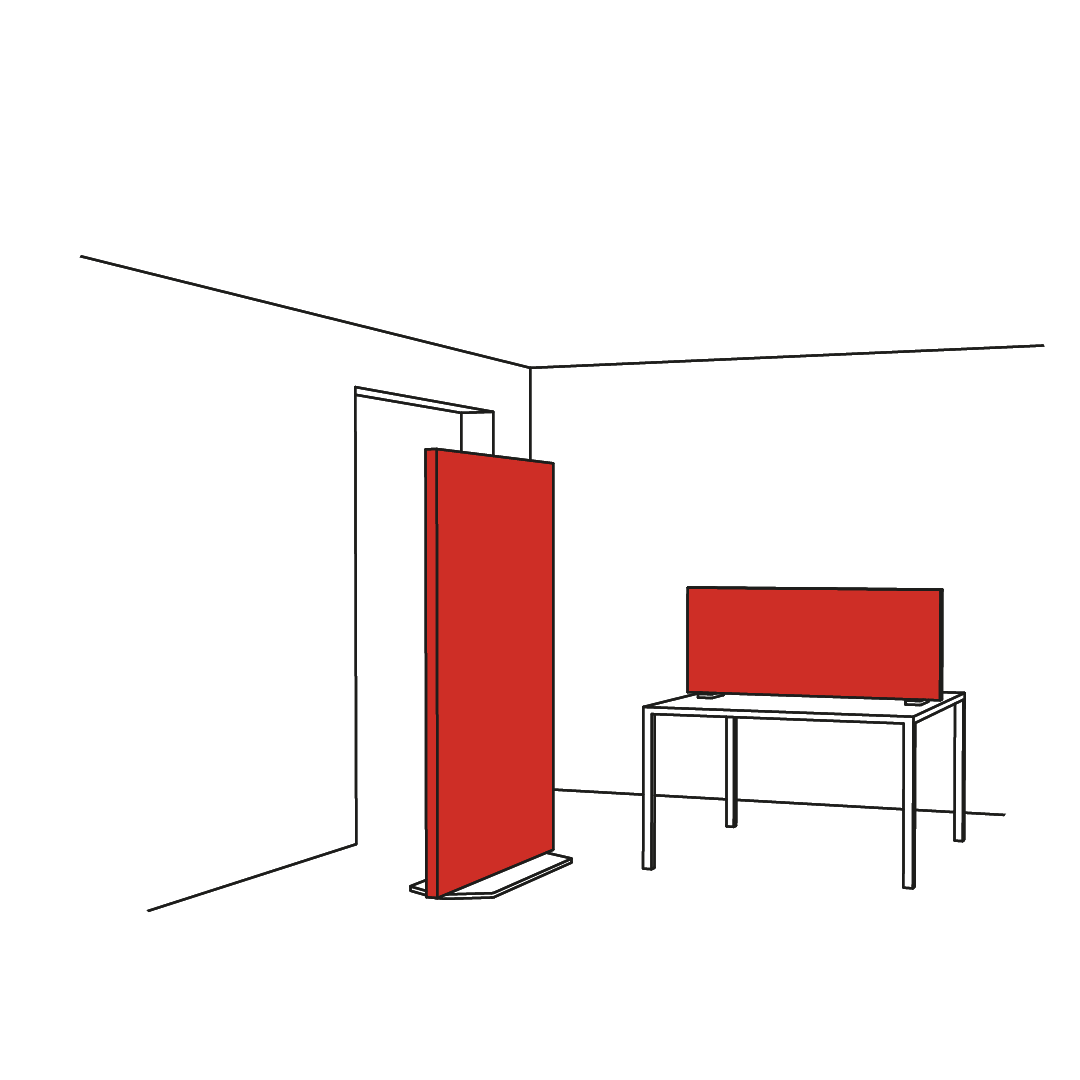

Designed to promote reuse, this centre serves both as a materials storage site and to provide support for small businesses that are developing and organising the materials reuse sector in the City. It also hosts a range of events designed to bring both professionals and members of the public together. “Part of the building is for conferences”, explains the architect Orianne Scourzic. As soon as we started using it, we quickly realised that we had to improve its internal acoustics. And a second challenge also became apparent, that of darkening the large glazed wall of this area, when we needed to project slides onto a large screen. And what if we could also find a solution that would enable us to continue to apply the reuse policy of the whole project?” In a discussion, Adrien Maillard (Director of the Maison d’Architecture in New Aquitaine) advised her to involve Texaa, and put the team in touch with Victoire Mondonnet, a designer, responsible for circularity issues and reuse in Texaa. “To respond to this type of request”, explains Victoire Mondonnet, “we turn to what we call our ‘sleeping stock’. This consists of all the materials that we don’t use to manufacture the products in our current range. They typically rotate very little. We recently devised an in-house tool that shows us real-time quantities of this stock, as well as the reconditioned products available; items, for example that have come back from exhibitions. What we needed, for example, for the Reuse Base project, we found with the tool.” Five 2.8-metre-long curtains in colour Bleu Étang had just been put in stock. What was really lucky was that the colour perfectly matched the graphic charter of the premises! But they were too short, so we had to find a way to make up the length required. Enter Thibaut Chédeville, joiner and cabinet-maker, and founder of Officine du Réemploi in Bordeaux, also in the project team with Orianne Scourzic. “He’s used to situations like this”, she smiles, “and what’s more that’s reuse; it’s all about adaptability!” Working with Texaa’s engineering team, Thibaut built a wooden pelmet to compensate for the missing length. Four of the five curtains were hung there and the fifth was used to cover the pelmet. With a little bit of collective genius and some time in the workshop, the conference area was darkened and its acoustics improved!

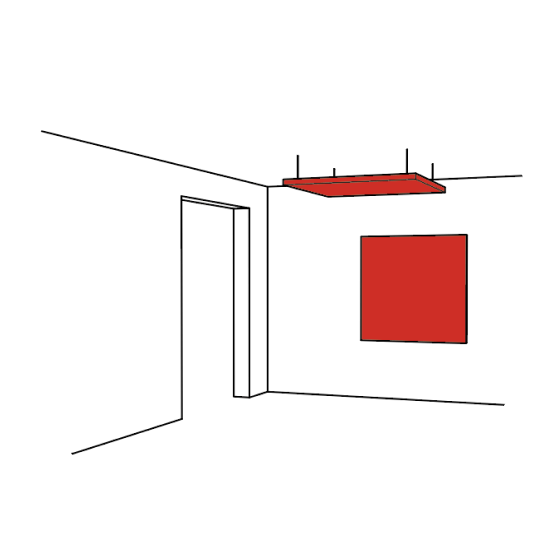

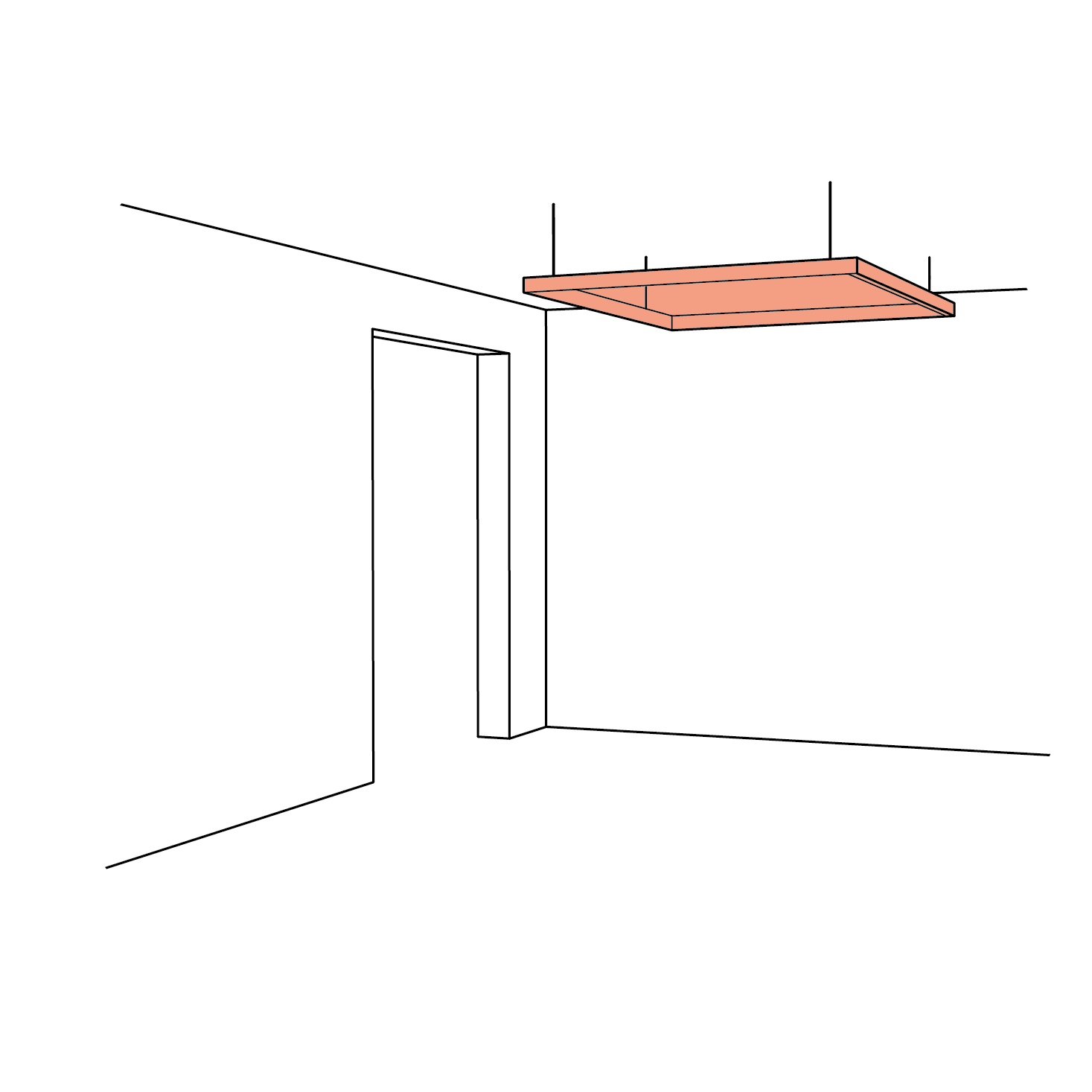

Materials to create something new

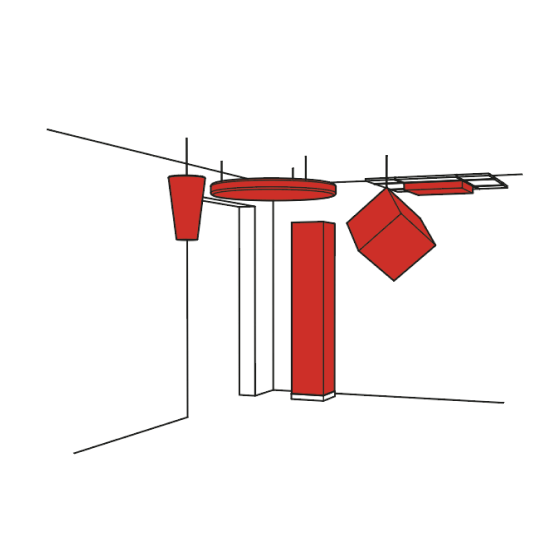

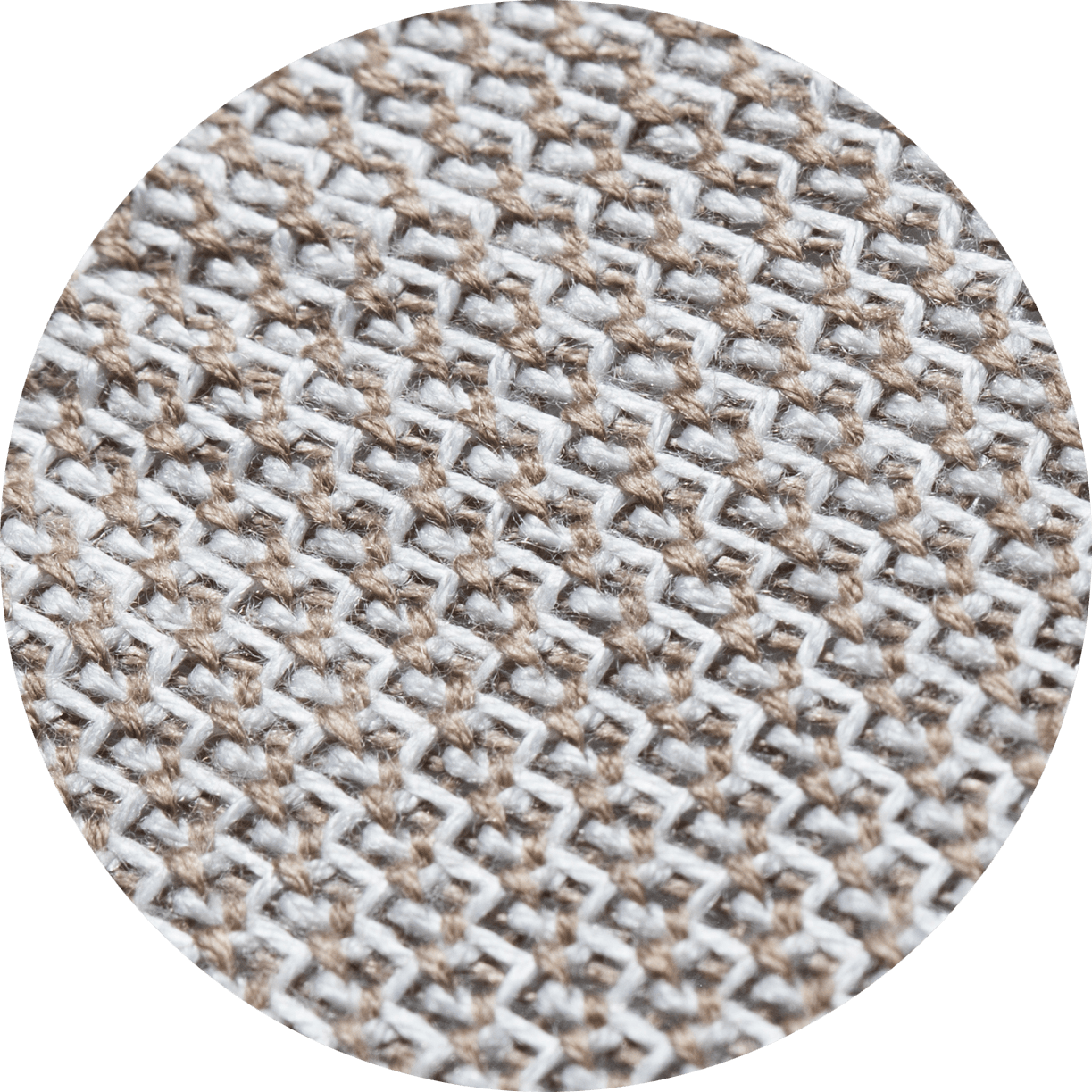

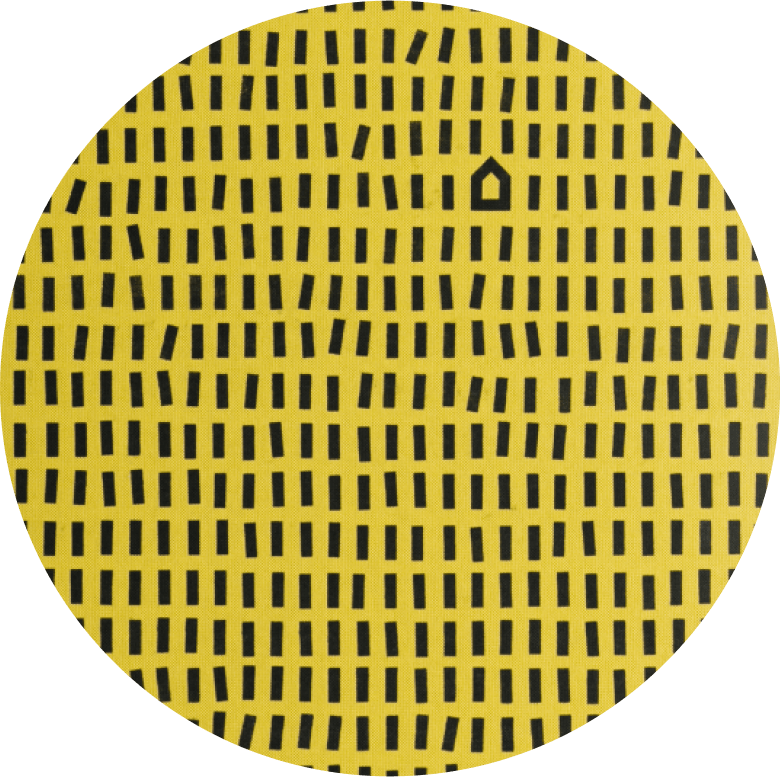

Victoire Mondonnet continues, “Sometimes also, our ‘sleeping stocks’ or production offcuts are used as primary materials for more demonstrative, artistic projects.” These are a kind of pilot project to show everything that can be done and created, when you apply reuse principles. Using ‘sleeping stocks’ of Aeria fabric in bright colours, Koz architects designed poufs, rugs and cushions as the basis for a temporary refit of the Grand Foyer of Paris’ Chaillot Palace. Closer to Texaa’s workshop in Le Bouscat, a northern suburb of Bordeaux, Virginie Linxe and Marie Lozano, the founders of Lieu Inspiré, a space devoted to books, used production offcuts of fabric from the Texaa workshop to cover a den, in which creative sessions for children are held. Another example of this was at the first Rencontres d’Architecture en Mouvement event, organised in Limoges in southwest-central France, when Texaa supported Nicole Concordet, architect and the event’s Artistic Director, in creating an immense acoustic tent for the conference area, made from the ends of rolls of Vibrasto acoustic cladding. Based on what was available in the ‘sleeping stock’, Nicole designed a colour sequence to match the visual signature of the locality. 185 pieces of fabric were joined up edge to edge and stitched with lovely red thread, to produce 12 strips, 14 metres long that made up the tent. Fantastic ways to give materials a new purpose, and in return to enable the ranges to grow in a circular way. “That’s what’s typical about these new practices: more work in order to consume less”, adds Matthieu Demptos. “This way of working and the patchwork techniques implemented during this project, led, for example, to a new “Patchwork” option for our Stereo panels. With a little more stitching, but with no increase in the quantity of fabric used, the panel takes on a new dimension. Its minimal look becomes rich and generous.” This year again, at the Rencontres d’Architecture en Mouvement held in Oloron-Sainte-Marie in southwestern France, prototypes of 6-metre long monumental curtains will be reused. Initially manufactured for a test in our workshop, in response to requests for extra-long curtains, they will contribute a little comfort to the banquet hall. So, how do we start another cycle of this virtuous circle? It just needs a phone call or an email. We always respond

Are our products fire-resistant?

Yes, our products are fire-resistant and comply with regulations governing public-access buildings.

Texaa solutions are tested for reaction to fire in accordance with international standards. Fire reaction test reports (fire certificates) are available upon request to support specification.

Please feel free to contact us by email at cf@texaa.co.uk or by phone at +44 (0) 20 7092 3435.

How can I get a quote?

By contacting the Texaa business representative of your region by telephone or e-mail and leaving your contact details and what you need. We will send you a quote promptly.

How can I order Texaa products?

Our products are manufactured in our workshop and made available to order. Just contact the Texaa business representative of your region. If you already have a quote, you can also contact the person handling your order: the name is at the top left of your quote.

How do I get my products installed?

Joiners and upholsterers are the best skilled to install our products easily. We work regularly with some professionals, who we can recommend. If you have a tradesperson, who you trust, we can support him/her. You can find our installation instructions and tips here.

Got a technical question?

All our technical data sheets are here. Your regional Texaa business representative can also help; please feel free to contact him/her.

Can I have an appointment?

Our business representatives travel every day to installation sites and to see our customers. Please feel free to contact them and suggest the best dates and times for you, preferably by e-mail.

Lead times

Our products are manufactured to order. Our standard manufacturing time is 3 weeks for most of our products. Non-standard products take from 5 weeks. We also perform miracles on a regular basis! Please feel free to contact us.

Who should I call?

To get a quote, a delivery time or technical information, we recommend you call your regional Texaa business representative, who you can find here.

Order tracking

If you need information about your order, please contact the person in charge of handling it: the name is at the top left of your quote.